Process and planning

A German manufacturer of frozen cakes and flans is using bespoke software from CSB-System to help maximise production and planning efficiencies and provide full traceability.

At Pfalzgraf Konditorei, the CSB-System is used as part of production scheduling with raw material requirements calculated from the recipe and the number of products to be manufactured, and then sent directly to suppliers.

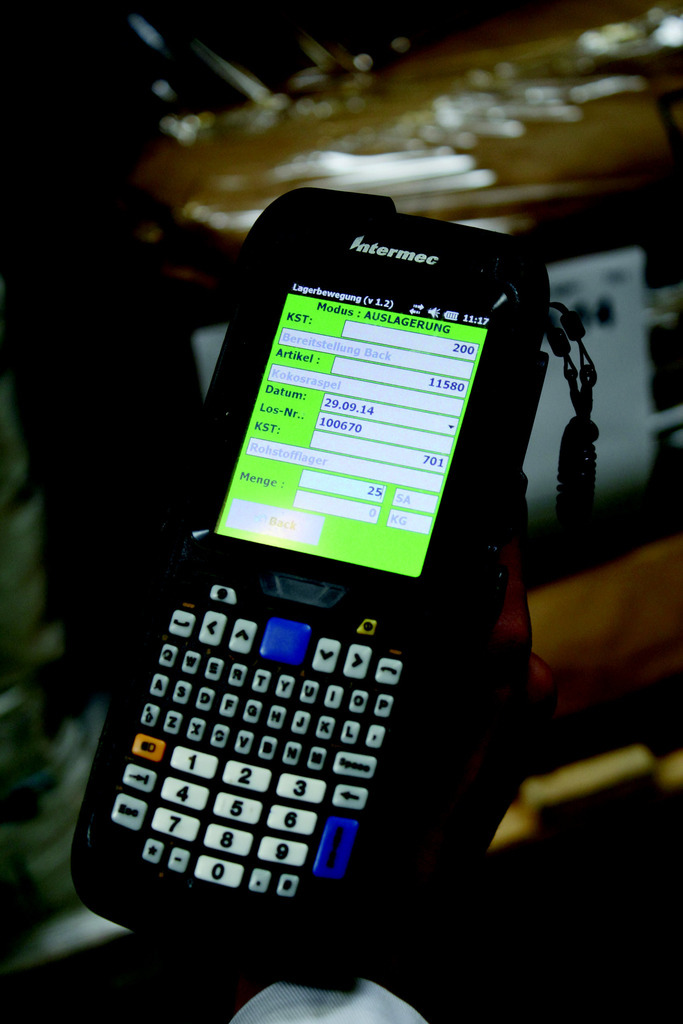

In goods receiving, this information is also made available along with other critical details for individual products such as shelf life or temperature storage requirements. Goods from suppliers which already have an EAN 128 bar code are scanned by a mobile data recording unit, which eliminates the need for the time-consuming manual inputting of information. Raw materials without this code are provided with a self-printed bar code label by warehouse staff, which includes all the relevant information for the subsequent stages.

For each production, goods are booked out as required and weighed and prepared in preparation rooms upstream of the four production lines. CSB-Racks, the company’s specially-designed industrial workstation for automated data capture, are linked directly to the scales and ensure that all required work steps are carried out in line with specifications. Operators have to confirm each stage on the screen for the process to continue, thus ensuring production and recipe consistency.

Following production, each finished cake and flan can be broken down by the system into its individual raw materials and primary packaging through the EAN-code and batch number provided by the CSB system. This enables Pfalzgraf to guarantee full traceability of its products – from receipt of goods, through production and to packing and dispatch – both internally and for its customers.

Pfalzgraf says the CSB solution is both effective and flexible.

“We also always have the option of approaching the CSB developers with our own ideas and suggestions in order to programme specific solutions that are tailored to our company,” explains IT manager Andreas Ziegler.

Another benefit is highlighted by Pfalzgraf’s Dirk Brünz: “Along the way we have also learned a great deal about our production processes and can optimise these further while implementing the software.”