Solution combines robotic palletiser with AGV

CSi and JBT have announced that the i-Pal palletiser can be integrated with the JBT JayBoT AGV to deliver a fully-automated, affordable end-of-line solution for producers of fast moving consumer goods.

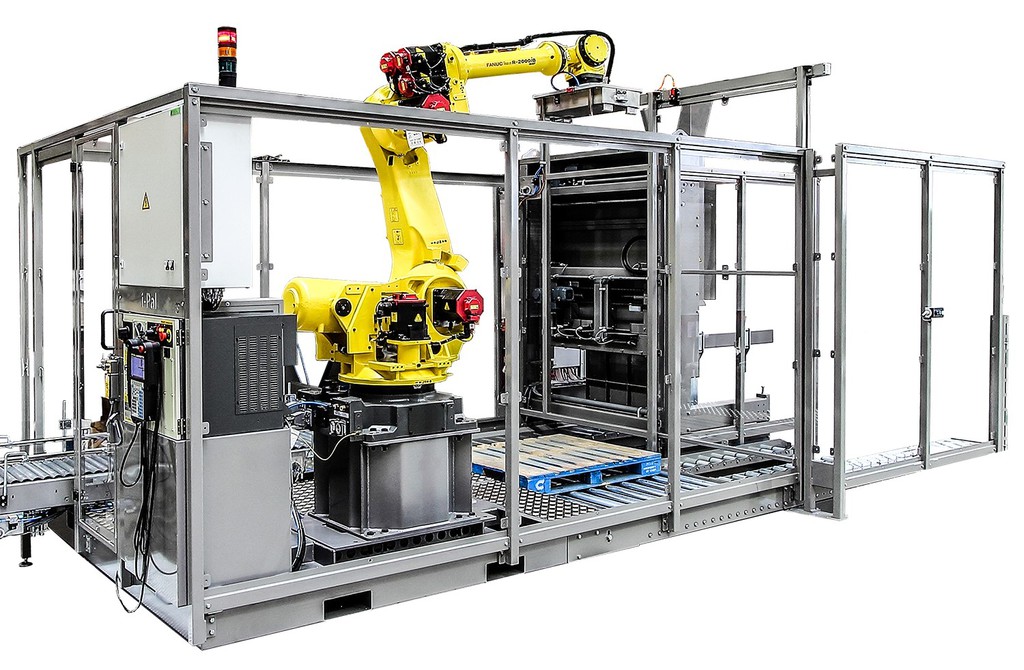

CSi’s i-Pal is a compact, modular palletising unit which includes a spherical robot and inlet/outlet pallet conveyors installed on a skid. With its universal gripper, the i-Pal can handle a wide range of products and stacking patterns with rates of up to 20 cases per minute.

JBT’s JayBoT AGV provides fully-automated pallet movement for simple applications without the complexity and cost of a centralised system manager and communications network.

{EMBED(640060)}

The JayBoT AGV communicates directly with equipment such as CSi’s i-Pal or other JayBoTs – a major breakthrough in AGV technology. Direct communication allows the i-Pal to "tell” the JayBoT to initiate a pallet exchange, remove a completed pallet, and deliver an empty pallet without a centralised system manager.

The integrated i-Pal/JayBoT solution offers palletising of the highest quality. Without the need for manual fork trucks and/or fixed pallet conveyors, traffic flow and safety are improved, costs and product damage are reduced, and productivity is increased, says the companies. CSi and JBT also supply custom palletisers and centrally managed AGV systems for larger, more complex end-of-line applications.