Optimise productivity at warehouse pack stations

Harting’s MICA modular industrial edge computer is at the heart of a system for workflow optimisation at warehouse packing stations that offers process optimisation.

It is said to achieve this through increased productivity as well as integrating incompatible hardware and software and simplifying the jobs of the packing operatives.

The system has been trialled at Harting’s own warehouse packing facility.

It is designed to address the challenges that are typically encountered where a customer order requires a wide range of separate component parts to be packed and shipped in one or more cartons.

{EMBED(964930)}

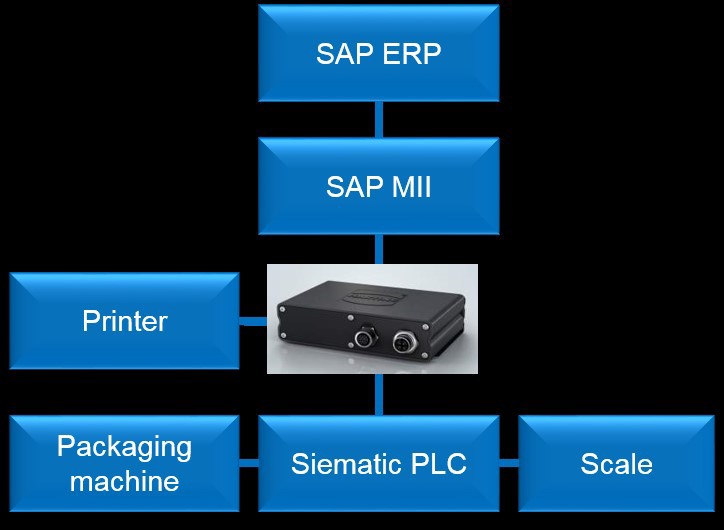

Previously, packers might have to interface with a range of different stand-alone computer control devices such as a weighing scale, a PLC that controls the packaging machine, and a printer for the labelling of the packaging films.

By integrating a MICA edge computer at the packing station, the new Harting approach combines all these actions.

Integrating an RFID antenna function module with dual antenna ports, makes it possible to identify both the tagged transport containers of packed parts and the employee’s personal ID card. The MICA computer can thus automatically log on and assign the packed parts to the employee’s unique identification record. As a result, the packing process information can be integrated directly into a piecework payment system.