| Home> | Automation | >Automated handling | >Defining the Smart Warehouse |

| Home> | Automation | >Automated storage | >Defining the Smart Warehouse |

| Home> | Automation | >Picking & sortation | >Defining the Smart Warehouse |

Defining the Smart Warehouse

21 November 2018

If you work in logistics, the chances are you have come across the term “Smart Warehouse”. But what does it mean, and how does it provide a powerful competitive edge?

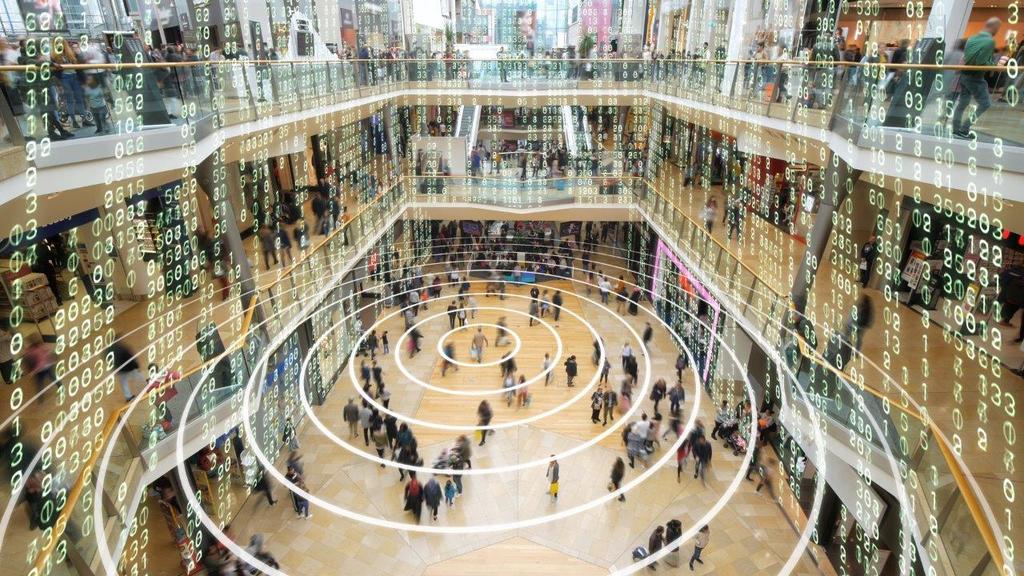

Whether we like it or not, the Smart Warehouse is here. It delivers significant advantages through its efficiency, speed, density and scalability. A Smart Warehouse is automated and connected, meaning that it is data-driven. The physical operation is integrated with the digital processes. The purpose is to cut the need for manual handling and increase the speed, quality, flexibility and efficiency of logistics processes.

Swisslog’s Head of Sales in the UK, Shane Faulkner puts it simply: “It describes the connection of all processes within a warehouse. Just like Industry 4.0 has been transferred to logistics, the Smart Warehouse is inspired by the Smart Factory,” he says.

- Award-winning technology for bespoke mixed case pallets

- Current trends reveal secrets of the future warehouse

- IKEA implements Micro-Fulfillment concept

- Making sense of picking strategies and technologies

- Swisslog cements number one slot

- Global pharma players bank on Swisslog

- Swisslog implements turnkey facility for leading European retailer

- Item picking robot works alongside people

- Swisslog delivers latest developments in eCommerce

- Swisslog to showcase PowerStore at Trinchero as part of World Automation Tour

/GRABOMATIC LOGO-tn.jpg)