| Home> | Automation | >Conveying components | >New oil-free drum motor |

| Home> | Industry Sector | >Food & drink | >New oil-free drum motor |

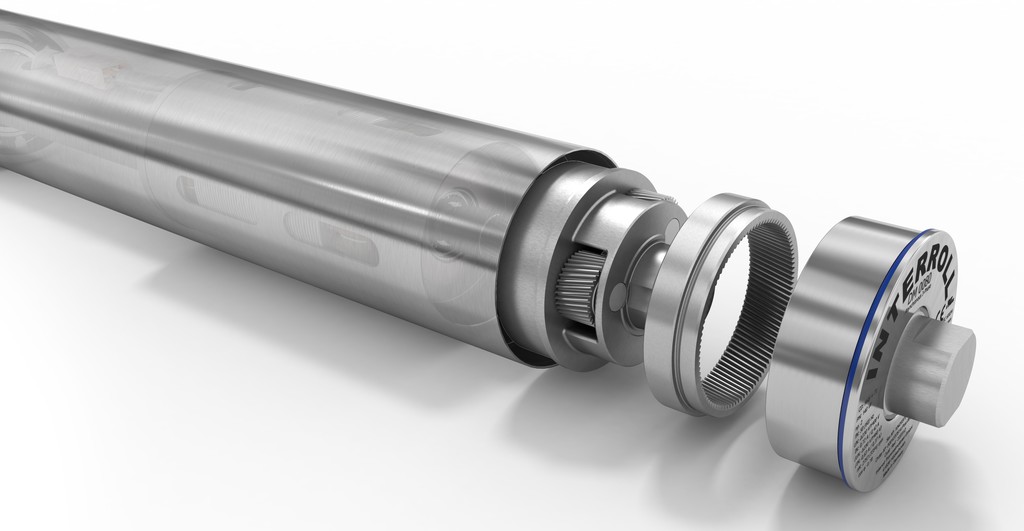

New oil-free drum motor

14 May 2019

Interroll is introducing a new version of its oil-free drum motor based on the new and improved Interroll Drum Motor Platform.

Interroll introduced the first oil-free drum motors in 2010. Since then, thousands of oil-free motors have been installed and are currently in use as a proven solution for many applications, in particular in the food industry.

The oil-free drum motors now being introduced into the market are drum motors based on the new and improved Interroll Drum Motor Platform that has been on the market since 2017. Synchronous oil-free drum motors are by nature very efficient, which means less heat losses and a much higher power density, as opposed to asynchronous oil-free drum motors which are prone to overheating and power reduction and therefore loss in torque.

Compared to standard drum motors, the oil-free motor’s performance is only minimally impacted by the different type of lubrication. Also, compared to a standard asynchronous motor, oil-free synchronous motors are stronger and better performing. But they require a frequency inverter and speed and torque are slightly reduced compared to a standard synchronous motor lubricated with oil. However, high-speed applications are still possible if the belt pull force is sufficient. This is also true for low-speed applications. Typical oil-free motor applications include transportation and packaging of lightweight goods such as candy, chocolate or pralines.

- Interroll Drum Motors drive against the conventional

- For dynamic solutions

- Magnetic speed controller optimises gravity roller conveyor operation

- Interroll expands drum motor platform and conveying solutions

- Centre of Excellence established

- Automated order picking system for DC

- Interroll to show off range of solutions at IMHX

- Key influences

- Survey reveals scope for further automation

- Interroll’s second plant in Atlanta starts operation

/GRABOMATIC LOGO-tn.jpg)