| Home> | Automation | >Automated handling | >Optimise warehouse process with intelligent systems |

| Home> | Warehouse IT | >Hardware | >Optimise warehouse process with intelligent systems |

| Home> | Automation | >Picking & sortation | >Optimise warehouse process with intelligent systems |

Optimise warehouse process with intelligent systems

06 September 2019

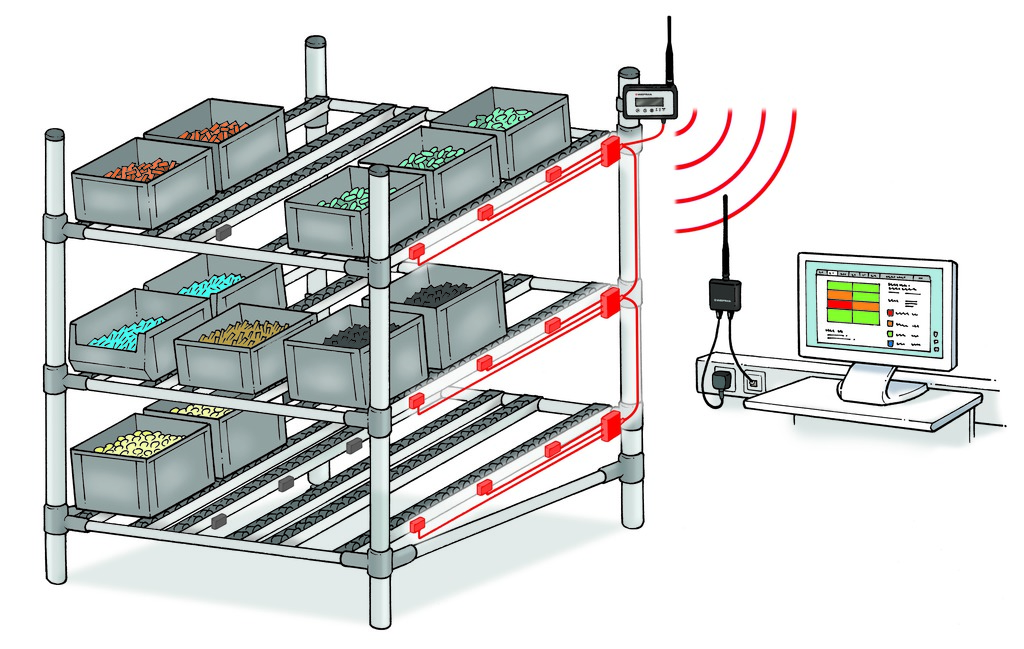

Werma will showcase a card-less Kanban stock monitoring and replenishment system StockSAVER at IMHX.

It uses intelligent monitoring points to monitor and manage line side stock levels and automatically generate replenishment calls wirelessly. Reduce line side stock, improve cash flow and optimise the Kanban process.

A second system, SmartMONITOR uses conventional andon lights but with the addition of a wireless transmitter and receiver kit will monitor up and down time of machines and equipment and also collect other relevant data on machine performance. Notification of machine downtime can be sent immediately to the department to rectify, helping to reduce costly machine downtime.

The company says: "We will also be demonstrating AndonSPEED, an andon light based wireless call for action system which is proving popular in many online retail warehousing operations as well as industrial operations, manual workstations, for example.. The system will identify bottlenecks in the warehouse system and speed up response to disruptions to production by notifying the team required to intervene."

In addition a range of our well known beacon and sounder devices will be on show including the very latest designs with new features.

- Managing traffic

- 3 in 1 LED traffic lights

- WERMA extends factory in Germany

- Speed up logistics processes

- Wireless remote switch

- WERMA once again rewarded as a Technology Leader

- Free seminar at The Lean Workshop Group

- Werma offers three easy to retro-fit wireless solutions

- Intelligent automation aids safety

- StockSAVER: the new Kanban system without cards

/GRABOMATIC LOGO-tn.jpg)