| Home> | Automation | >Automated handling | >Slicker accumulation process |

| Home> | Industry Sector | >Food & drink | >Slicker accumulation process |

Slicker accumulation process

06 June 2019

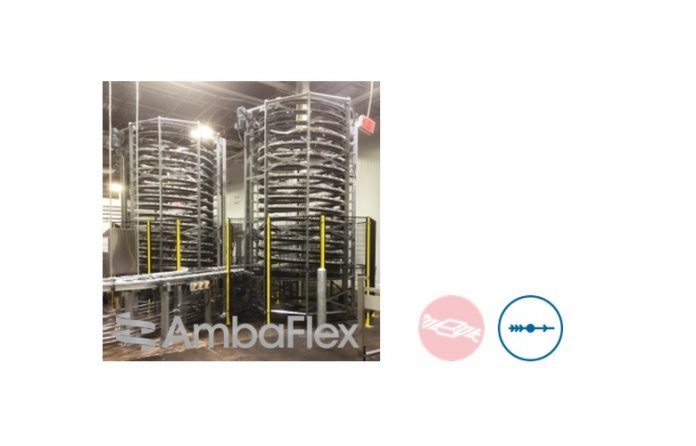

Ambaflex helped a ‘ready meals’ firm in the USA optimise its production lines.

Part of the line concerned individual packs being packaged into larger cases for transport and this could be problematic.

These types of machines are prone to disruptions and even though they are often quickly resolved they also force the top-seal machine to a stop. The stoppage of the top-seal machine is problematic as a whole series of boxes have to be written off as waste as the special conditioning process only works when the whole process is running at full speed. These types of products have a difficult shape and tend to give accumulator systems a lot of trouble.

The answer was the use of a set of AmbaFlex AccuVeyors AVh machines. Because these spirals only use a single belt, there's no need for a product transfer unit or, as used in low-end accumulators, systems that work on pressure. The products stay on their respective place on the belt throughout the whole accumulation process. There is no pressure put on the product and it is kept on a first-in, first-out principle.

- Science in spirals

- Chinese spiral conveyor copier stopped

- Dynamic accumulator

- Slat innovation launches

- Space saving solution

- Spiral conveyor record

- Flexible belt slat technology

- Custom conveyor can run multiple parallel tracks independently

- Online grocery handling solution

- Spiral conveyor sent to China

/GRABOMATIC LOGO-tn.jpg)