End-to-end performance

Exotec’s new generation of Skypod aims to provide an end-to-end robotic warehouse solution. Logistics Matters editor Simon Duddy jumps the Eurostar to hear more.

EXOTEC’S SKYPOD system was a game changer when it launched less than a decade ago, with its rack climbing robots causing a logistics sensation. Since then, Exotec has become a thriving global solution provider with a blue chip range of customers across a range of industries.

Now the French innovator has updated its robotic system, and perhaps unsurprisingly, has taken a very ambitious approach to this. The key focus is not simply hardware and software improvements, although there is that, but also a broadening of the scope of what Exotec is seeking to cover in terms of warehouse processes.

Exotec CEO and co-founder Romain Moulin, says: “We’re already seeing our customers reimagine their entire supply chain around the transformative capabilities of this innovation, from combining case and each picking operations, to leveraging outbound sequencing to improve transportation costs. Witnessing this level of impact has been incredibly rewarding.”

I asked Romain how he saw the system differentiate itself from warehouse cube storage systems.

“The new-gen Skypod does what a cube storage system would need other equipment to do, and does so more simply and elegantly within one system. Other systems would need a buffer, sequencer and palletiser from other providers, as bolt-on parts, which takes time to assemble, and adds cost and complexity.

“We see ourselves as solvers of problems in the business of logistics, not as a robot provider. Robots are great of course, but customer focus is key – to not walk past the customer problem by focusing on tech for its own sake. It’s not about the speed of the bot, it’s about solving complex logistics problems with simple elegant solutions.”

A key differentiator is the ability to natively support a number of value-added logistics features that traditionally require external equipment and complex subsystems. This not only enables customers to simplify the flow of goods through the warehouse, but also significantly shrinks the system footprint by cutting down the need for conveyors, sorters, external storage, and packing stations.

Exotec developed next-gen Skypod in response to evolving market needs and feedback from its existing customer base, which increasingly demands warehouse robotics to address a wider range of processes within the warehouse walls. Over the past two years, Exotec has sold and deployed the new Skypod system globally in stealth mode. The company has successfully secured over 20 projects worldwide.

Hypermarket E Leclerc Seclin finds the new system useful.

CEO Maxence Maurice says: “We chose Exotec for its storage density and its operational flexibility. Robotic advancements have enabled us to set up a larger buffer area for prepared orders within the system.

“Previously, I estimated that the customer journey, from arriving at the pick-up point to leaving with their groceries, took between 10 and 15 minutes. Today, with the Exotec solution, it takes less than 5 minutes.”

Integrator journey

The most obvious business benefit to Exotec is that it opens the company up to larger value contracts, for example, as well as providing a £5 million ASRS via an integrator for a client, they can manage a £100m warehouse automation contract directly.

So does Exotec see itself as a manufacturer or as an integrator?

Both says Exotec chief revenue officer Arthur Bellamy.

“We can provide a standardised ASRS with partner integrators, that’s 20% of what we do. On the other hand, 80% is Exotec being an integrator. On these projects, we generally use 70% Exotec products and 30% other solutions, but in the end the client wants an end-to-end solution, not robots but a logistics solution.

“We have had rollouts with customers involving multiple sites across the world, and we have active opportunities with 40% of clients.”

The nuts and bolts

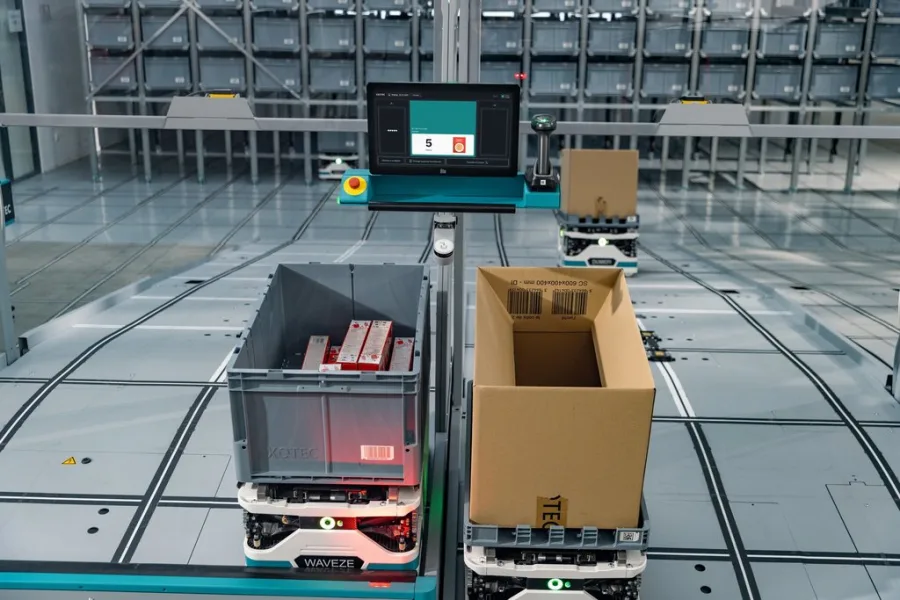

The new system features a new and more compact Skypod robot, a workstation for robot-to-robot picking, a high-throughput exchanger and denser storage. These redesigns, combined with new software features, improve the throughput at a single workstation by 50%, while enhancing storage density by up to 30% compared to the previous generation.

Suitable for both each and case picking, Skypod integrates advanced features like automated buffering, perfect sequencing and pick-and-pack, reducing the need for conveyors, sorters, and external storage.

Integrated buffer: Next-Gen Skypod handles buffering within the system. Following order preparation at the workstation, completed or semi-completed orders get automatically stored inside the racks until they are ready for outbound, or further consolidation. This helps reduce the need for staging areas or any other external buffer systems.

Perfect sequencing: Next-Gen Skypod handles strict outbound sequencing before ejecting orders by using robots and the exchanger. The robots group orders and delivers them in a specific arrangement to the exchanger, which then routes the orders to outbound. This enables precise loading of pallets, containers, or trucks based on delivery routes, store planograms, or other unloading requirements, all without the need for external sorting equipment.

Software is key, with the Exotec system using both AI and Maths optimisation.

Romain says: “This allows customers to plan ahead, from the correct order of picking, as well as using the buffer to make sure items are in the correct order for despatch, in the most useful order to the van driver, for example.”

Pick-and-Pack: Next-Gen Skypod handles packing as an integrated part of the picking process, with automated technology provided by Packsize among the solutions integrated. Operators pick directly into fulfilment containers, removing the need for manual packing operations downstream. This functionality pairs extremely well with right-size packaging solutions. These solutions can be integrated with Next-Gen Skypod to enable picking into right-size containers, significantly cutting last-mile costs.

For more information, visit www.exotec.com