| Home> | Automation | >Conveying components | >Interroll expands drum motor platform and conveying solutions |

Interroll expands drum motor platform and conveying solutions

31 July 2018

Interroll will present its range of conveyor components and integrated drive solutions at the PPMA Show 2018 (25-27 September) at the NEC in Birmingham.

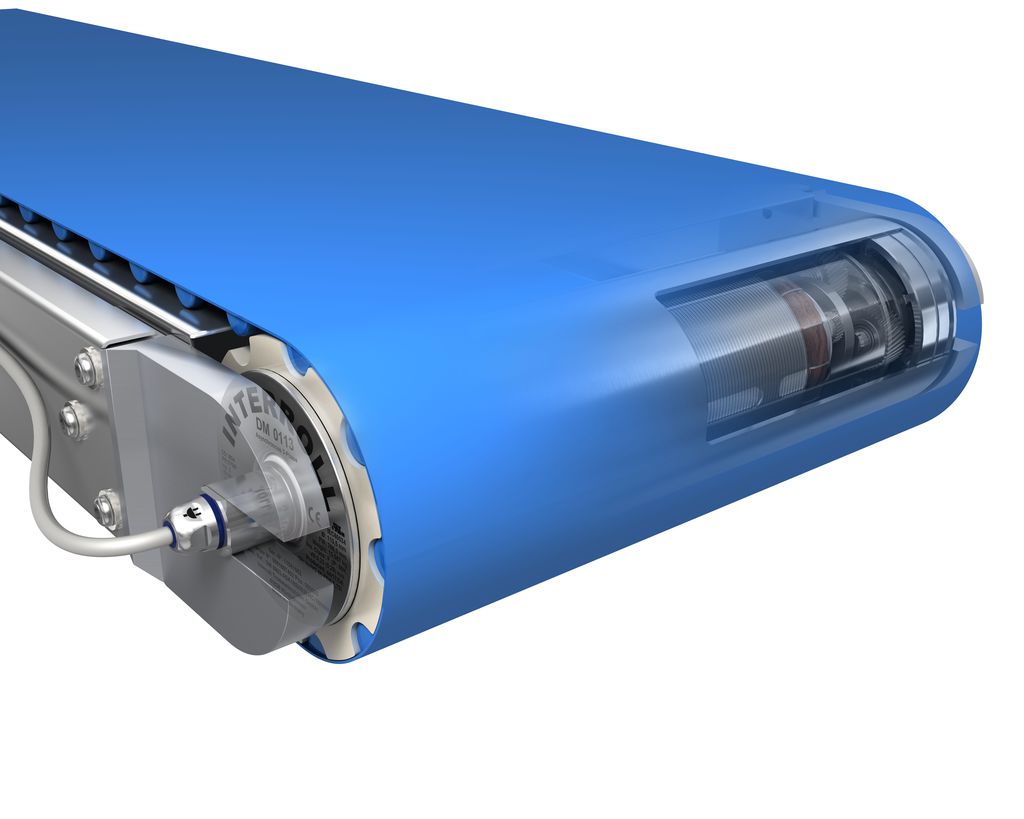

Following on from the introduction of the new modular designed drum motor platform last year, Interroll will highlight the expansion of the range from 80mm diameter drums and debut details of the new DM0113 and the DM0138, all available with an Asynchronous or Synchronous motor winding. Predominately used in belt conveyor applications, each motor is tested and designed in modular fashion in such a way that it can be delivered in the shortest possible time.

The new generation of drives offer an impressive range of benefits: Stronger shafts and ball bearings ensure an extra-long lifespan and the extremely stable design with a planetary gearbox allows higher torque to be transferred with low levels of operating noise. All the drum motors in the new generation comply with the requirements of IP69K, the highest degree of hygiene protection, meaning that they are significantly quicker and easier to clean in comparison to traditional gear motors.

Energy efficient 24V drive technology

Interroll will also display the 24V EC310 RollerDrive. By contrast conventional roller conveyor systems are equipped with a drive in continuous operation, the Interroll RollerDrive makes it possible to build up an intelligently controlled conveyor system divided into zones. Therefore, the drives of each individual conveyor section are only powered when material is actually conveyed.

At throughput rates of 600 to 1,800 units per hour, this achieves energy savings of up to 50 per cent by comparison with continuously running motors. Moreover, thanks to the demand-driven operation and the elimination of additional driving mechanisms, the noise level and the possible wear are substantially lowered as well.

To discuss possible drive or material handling solutions, visit the Interroll PPMA Show - Stand: F10 or visit the website - www.interroll.co.uk

- NEW - Interroll Light Industrial Belt Conveyor

- Space saving unit promises low noise operation and extended belt lifetime

- Interroll demonstrates excellence through innovation

- Interroll to present smart drive solutions

- New drum motors head for Interroll

- Interroll’s second plant in Atlanta starts operation

- Modular solutions for automated pallet conveyance

- Get your motor running… but not too hard

- Conveyors for chilled and deep-freeze areas

- Interroll sorters an eCommerce solution

/GRABOMATIC LOGO-tn.jpg)