| Home> | Automation | >Automated handling | >Caps two bottles a second |

ARTICLE

Caps two bottles a second

12 December 2012

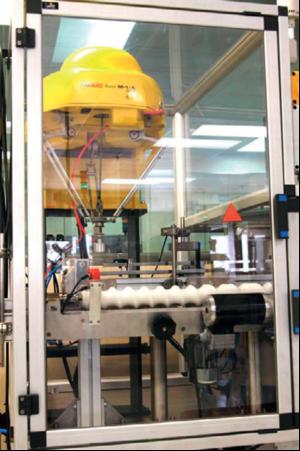

A Fanuc M-1iA Delta Arm robot has recently been commissioned on a bottling line at the Guadalix, Spain, facility of pharmaceutical manufacturer Merck. Placing dispenser caps on to bottled allergy medications, the M-

A Fanuc M-1iA Delta Arm robot has

recently been commissioned on a

bottling line at the Guadalix, Spain,

facility of

pharmaceutical

manufacturer Merck.

Placing dispenser caps on to bottled allergy medications, the M- 1ia is capable of operating at 120 cycles per minute.

Integrated by Fanuc systems partner Tecnomecánica, the M-1iA needed no special clean room compliance as the caps are placed on to filled and sealed bottles - the final operation before packing.

A spiral conveyor on the robot cell lines up dispenser caps on a rail and a nylon worm drive positions bottles alongside. The robot grips a cap and places it on the bottle, which has previously been sealed by a screwon cap. A simple encoder supplies the position data.

The M-1iA signals the worm drive to position the next bottle. A cylinder arrangement after the robot cell firmly presses the dispenser caps down onto the bottles.

The capped bottles are then conveyed to the packaging machine.

Placing dispenser caps on to bottled allergy medications, the M- 1ia is capable of operating at 120 cycles per minute.

Integrated by Fanuc systems partner Tecnomecánica, the M-1iA needed no special clean room compliance as the caps are placed on to filled and sealed bottles - the final operation before packing.

A spiral conveyor on the robot cell lines up dispenser caps on a rail and a nylon worm drive positions bottles alongside. The robot grips a cap and places it on the bottle, which has previously been sealed by a screwon cap. A simple encoder supplies the position data.

The M-1iA signals the worm drive to position the next bottle. A cylinder arrangement after the robot cell firmly presses the dispenser caps down onto the bottles.

The capped bottles are then conveyed to the packaging machine.

MORE FROM THIS COMPANY

- Shelf-ready case loading

- Mid-range line builder solution

- Palletiser aimed at high volume applications

- Automated foam handling

- Robotic loading system allows flexibility for packaging lines

- Robotic solution for mixed product pick

- Collaborative robot

- AFFORDABLE ROBOTS OUT IN FORCE

- FANUC groups & rebrands

OTHER ARTICLES IN THIS SECTION

/GRABOMATIC LOGO-tn.jpg)