| Home> | Automation | >Conveying components | >Non-contact profiling |

Non-contact profiling

06 June 2014

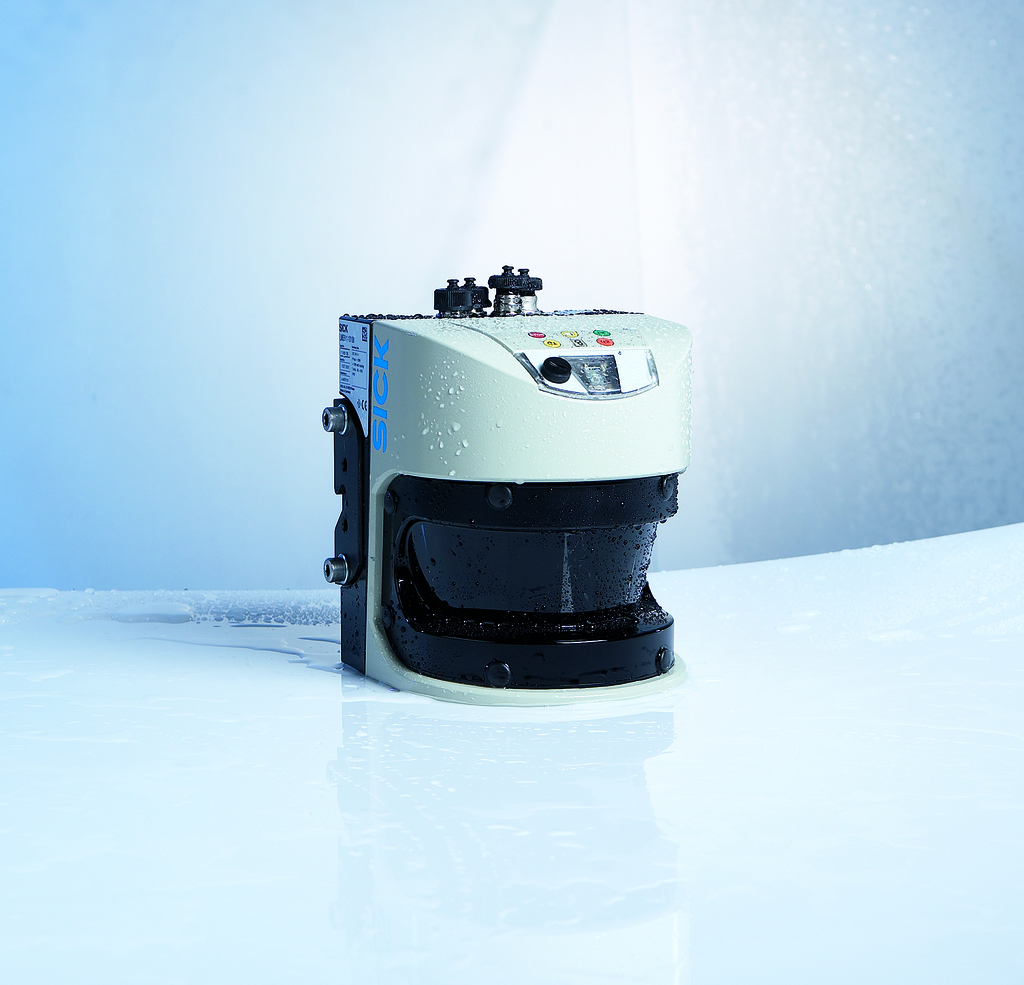

Measuring the volume and mass throughput of bulk materials on a conveyor belt has been made quicker and more accurate with the introduction of SICK’s LMS511 Bulkscan laser scanner.

Operating inside or outside under any weather or industrial conditions, the LMS 511 provides bulk material processors, shippers and storage handlers with a real-time measurement system that is almost maintenance free.

"Fixed above the conveyor, the SICK LMS511 Bulkscan tracks a highly-accurate and continuous non-contact profile of the materials on a conveyor belt, with a data update in less than 15 millisecond increments,” explains Darren Pratt of SICK UK. "It will operate reliably in the presence of dust, rain or snow and in ambient temperatures ranging from -30 and +50˚C.”

- Deploy SensorApps to help people social distance

- Quick reading even in tough applications

- Barcode scanner for industrial use

- Displacement sensors launched

- IO-Link connections just ‘make sense’

- Long range distance sensors to avoid yard collisions

- New compact code scanner series

- Muting sets on the fast track

- Smart Box Detection launches

- Simpler and easier robot guidance

/GRABOMATIC LOGO-tn.jpg)