| Home> | Automation | >Automated storage | >New dimensions in automated storage |

| Home> | Industry Sector | >Distribution | >New dimensions in automated storage |

| Home> | Industry Sector | >Manufacturing | >New dimensions in automated storage |

New dimensions in automated storage

19 March 2015

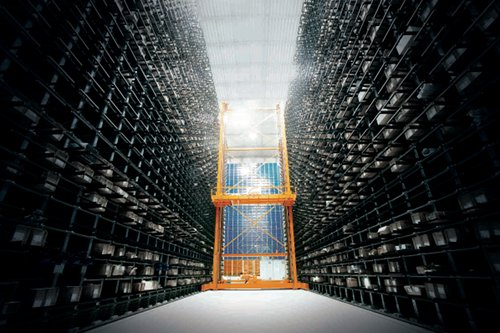

KASTO designs, manufactures and project manages the installation of a vast range of automated warehouses and other computer controlled storage and retrieval systems for bar, tube, profile, sheet and other items.

Raw materials can be stored alongside part-finished goods, pallets, stillages and boxes. The computer controlled systems may be interlinked with machine tools, robotic sorting equipment, MRP and ERP systems, and more. If a factory or stockholding operation is running out of space, one of KASTO’s minimally-manned, 3D solutions will be ideal for the user’s application and budget.

Such systems, which are manufactured to Industry 4.0 standards and also comply with them, reduce labour costs, maximise machining uptime, minimise damage to material, are safe to use and ensure short lead times through efficient storage, management and retrieval of stock.

Some of the options: KASTOunicompact honeycomb bar storage systems; KASTOlift, a compact storage system designed for workshops and small to medium-sized companies; KASTOunibloc stacking cradle systems; KASTOunitower cassette storage for steel and other service centres, and for storing small quantities of raw material and parts in job shops and other types of manufacturing operation; KASTOuniportal gantry-type cassette systems; KASTOunitop automatic bar storage systems with an operating crane travelling on top of the shelf block; KASTOunigrip for inexpensively storing loads up to 3 tonnes to 15 metres high; KASTOuniflex longitudinal storage; and KASTOuniline single- or double-sided storage systems for sheet metal applications.

- Kasto unveils storage innovation

- KASTO opens subsidiary in Singapore

- Invest to progress

- Robotic handling of steel material

- Interest in automation growing

- Upswing predicted in automated storage

- Kasto wins handling safety award

- Flexible storage for steel specialist

- KASTO to make MACH debut

- Steeled for growth

/GRABOMATIC LOGO-tn.jpg)