| Home> | Automation | >Automated handling | >Reliable Interroll conveyor technology products for use in refrigeration applications |

| Home> | Automation | >Automated storage | >Reliable Interroll conveyor technology products for use in refrigeration applications |

| Home> | Warehouse Storage | >Cold storage | >Reliable Interroll conveyor technology products for use in refrigeration applications |

Reliable Interroll conveyor technology products for use in refrigeration applications

13 July 2015

The market for temperature-controlled foods is becoming increasingly important, with logistics processes for refrigerated or frozen foods offering more challenges and demands. The industry is extremely energy intensive and strict hygiene and labor protection requirements must be taken into consideration throughout the entire production chain.

Logistics solutions must be designed to suit different conditions and temperature ranges as low as -30 °C in deep-freeze areas. This also applies to conveyor rollers because the technology needs to be able to work reliably in these environments.

Conveyor rollers in the frozen food zone

Materials shrink differently at very low temperatures, such as metal tube and techno polymer parts contained in a conveyor roller. In critical cases, such as unfavorable tolerance pairings with pure press fit connections, the drive head can rotate inside the tube. In such cases, driven conveyor rollers will be rendered useless.

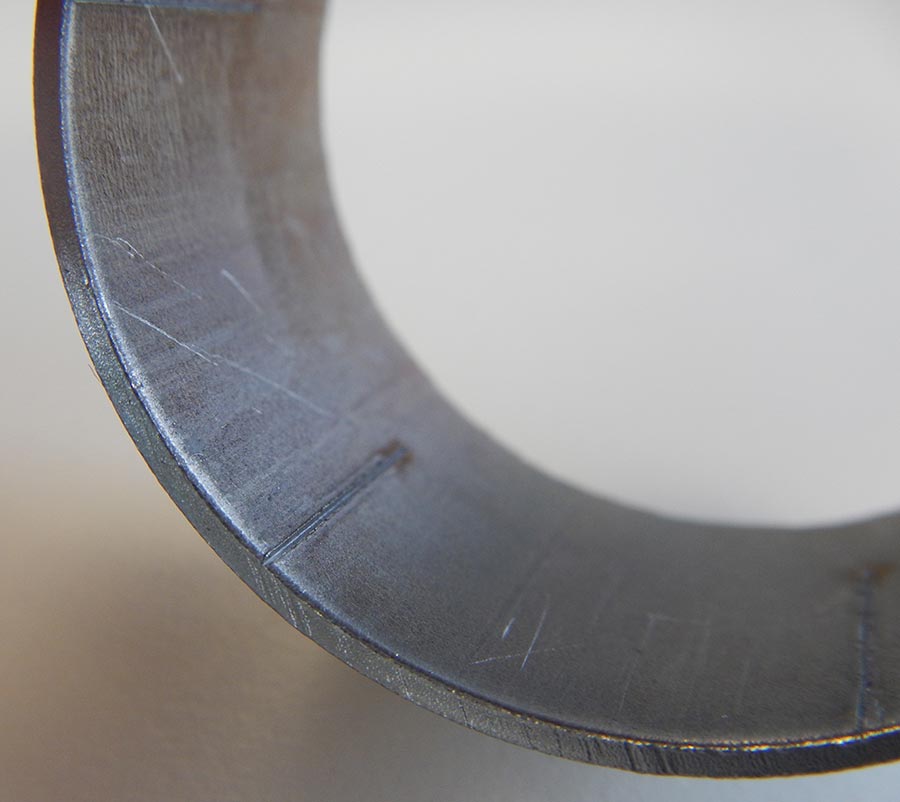

Fig.1 This photo shows a tube for a conveyor roller or motor roller that features the furrow created by the star.

To ensure failsafe security in operation, Interroll deep-freeze conveyor rollers are not only flanged at the tube, but also equipped with a metal star shaped - fitting to provide a positive grip and secure the roller endcap. The extremely sharp spikes of the star furrow (see Fig.1) into the tube interior to firmly connect the roller endcap on insertion and there are no protruding external edges that could damage packages being conveyed (see Fig. 2).

Comprehensive application and recurring dynamic load testing in deep-freeze environments has proven Interroll product quality.

Fig. 2 This photo shows the inside of a Poly Vee roller base with a lodged in star for creating a form fit.

Avoid replacement and maintenance costs

The reliability of component products is extremely important. Interroll products such as motorised rollers or conveyor rollers are designed and proven, which can save a lot of money by avoiding maintenance and component replacement time.

Perfectly harmonised components extremely important

Compatible components are essential to every plant and conveyor system to ensure optimum functionality. For this reason, Interroll offers a product package for zero pressure accumulation (ZPA) roller conveyors. Power supplies, cables, control boards, sensors, conveyor rollers, motor rollers, drive belts & O-rings and assembly tools are designed for use under deep-frozen conditions. (see Fig. 3 )

Fig. 3 This photo shows a conveyor roller from the 3500 Series with a Poly Vee head.

Energy efficient 24 volt drive technology

Drives influence energy consumption when they transport products. The energy costs in a cold storage area can account for up to 25 percent of the overall operating costs. With an Interroll 24 Volt RollerDrive, energy consumption can be reduced by around 50 percent compared with conventional 400 volt technology at medium throughput volumes of 600-1,000 containers per hour.

- Survey reveals scope for further automation

- Convert pallet racking into carton flow store

- Drum motor makes the cut

- Centre of Excellence established

- A novel solution

- Interroll presents dynamic storage

- Interroll joins AMHSA

- Interroll sorters an eCommerce solution

- Getrag Ford Transmissions gear up with Interroll Dynamic Storage

- Optimum solution for 24V DC conveyor technology

/GRABOMATIC LOGO-tn.jpg)