| Home> | Automation | >Automated handling | >LEO's introduction |

LEO's introduction

12 October 2016

At IMHX 2016, BITO Storage Systems introduced a new driverless intralogistics transport solution that is easy to implement, adapt or remove and does not require any permanent fixtures.

LEO LOCATIVE is ‘low-level’ Automated Guided Vehicle (AGV) that follows tape laid on the floor, which can be added to or removed whenever required. It does not require a Wireless Local Area Network (WLAN) or a central control computer.

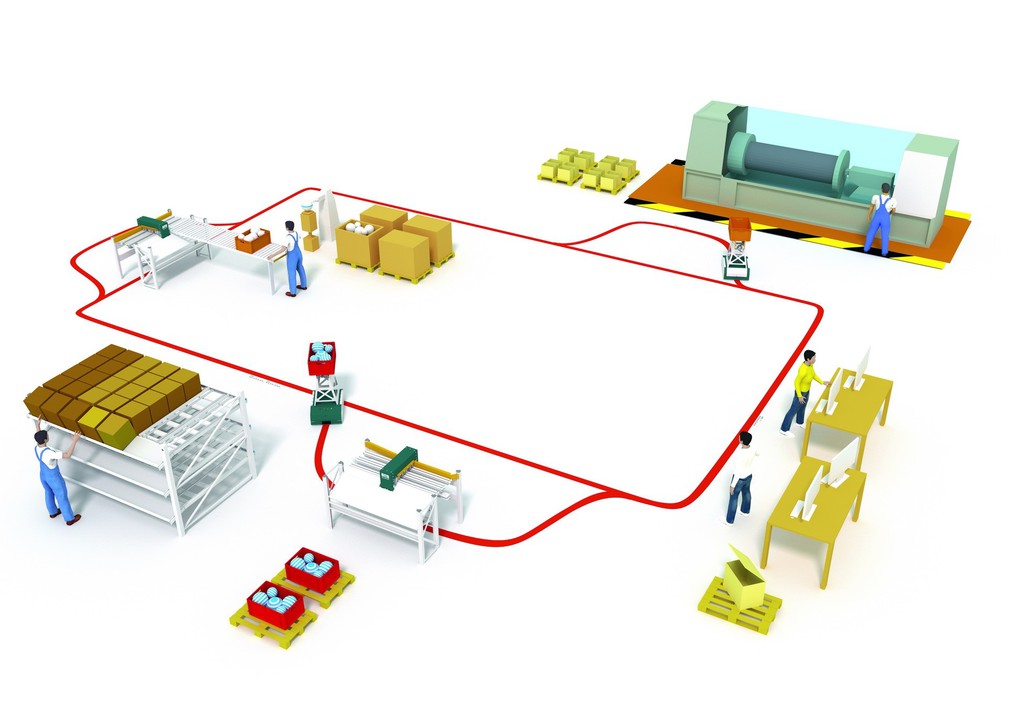

This provides an agile, user-friendly option for all kinds of order picking operations and is particularly useful for ecommerce, order picking peaks and assembly processes. LEO can connect production lines with the warehouse, receiving area and shipping area – reducing the risk of damage and the need for manual handling of heavy loads.

Implementation is a simple ‘stick and start’ process: red marker tape, which provides an optical track to guide LEO, is laid out as a closed loop.

/GRABOMATIC LOGO-tn.jpg)