| Home> | Warehouse Storage | >Racking & shelving | >Kanban system without cards adds efficiency to FIFO racking |

Kanban system without cards adds efficiency to FIFO racking

04 April 2017

WERMA has launched StockSAVER -the new generation Kanban system without cards.

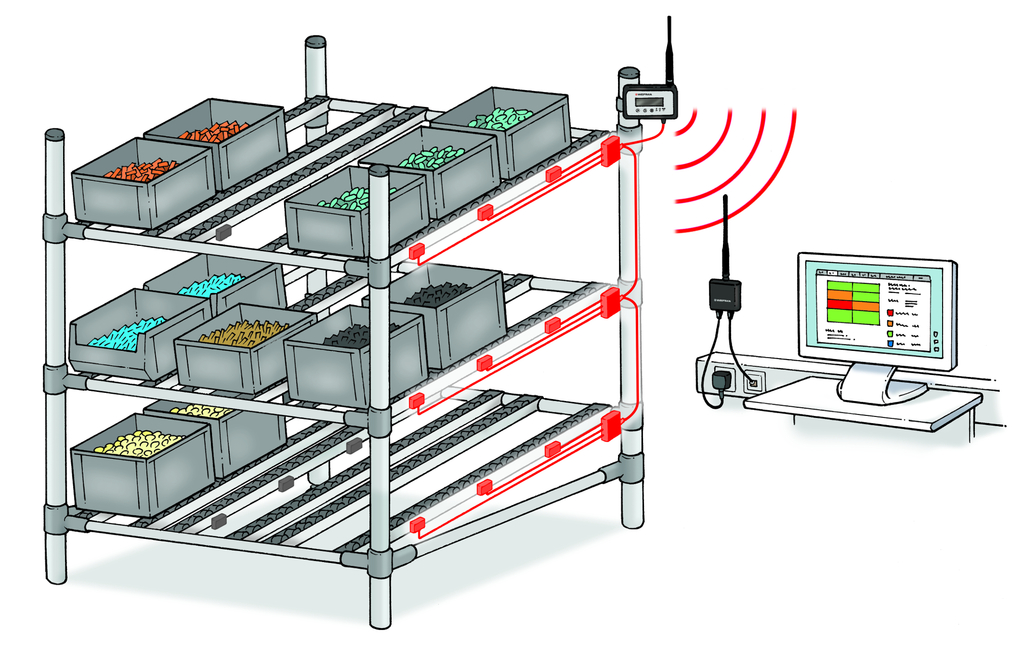

The system, simple to retrofit to existing FIFO flow racking, is said to solve many typical Kanban issues, increasing significantly the floor space for value adding activities and increasing cash flow. StockSAVER automatically calls up material replenishment requirements and thereby reduces the margin for human error and will cut the amount of line-side safety stock being held.

According to WERMA, few Kanban systems are completely free from errors and weak spots such as: Kanban cards not being processed promptly; cards being mislaid or damaged; and just missing the milk-round for collection of cards.

WERMA’s StockSAVER can resolve these issues and can reduce margins for error in other ways too as stock withdrawals from a rack no longer have to be scanned. No more manual arithmetic calculation of stock levels being held line-side is required either.

How does it work? Intelligent sensors are fitted to the FIFO racking giving total transparency of stock levels. Replenishment is automatically called up once the sensor detects the bin has been removed. Data is wirelessly transmitted to the control station view and database giving transparency on stock levels and replenishment orders.

- Process optimisation

- Andon light kit

- Industry 4.0 process optimisation

- WERMA once again rewarded as a Technology Leader

- Optimise warehouse process with intelligent systems

- WERMA UK joins the North East Automotive Alliance

- Wireless remote switch

- For safe & efficient logistics operations

- Call for action system

- Avoid packing line bottlenecks

/GRABOMATIC LOGO-tn.jpg)