| Home> | Distribution | >Transit Packaging | >New stretch hooder can be used in corners |

New stretch hooder can be used in corners

10 May 2017

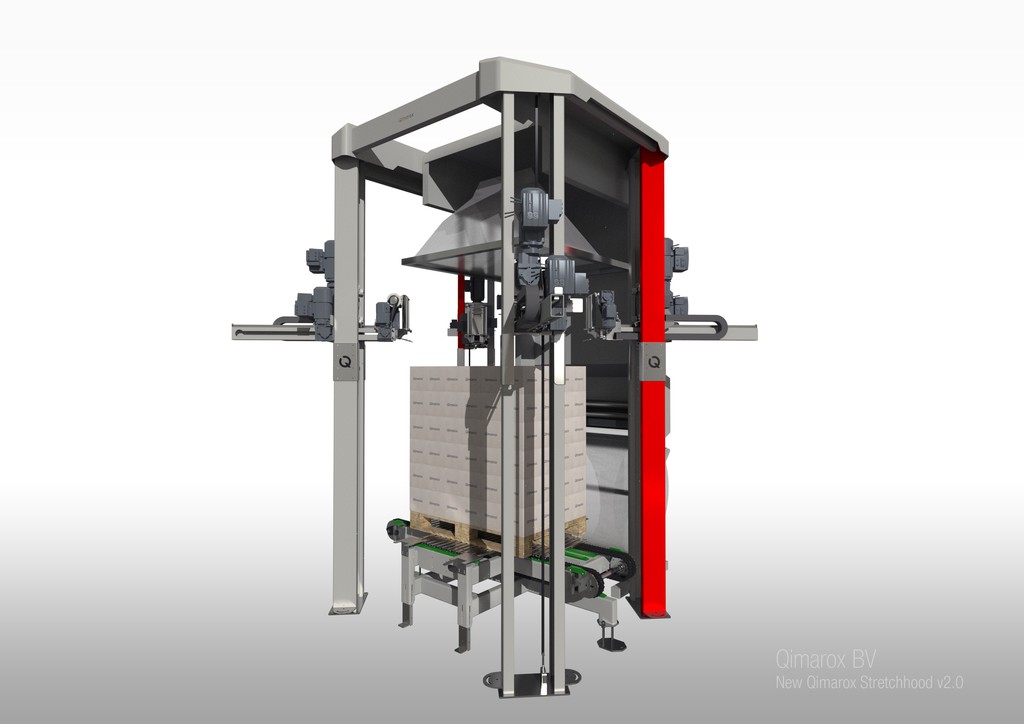

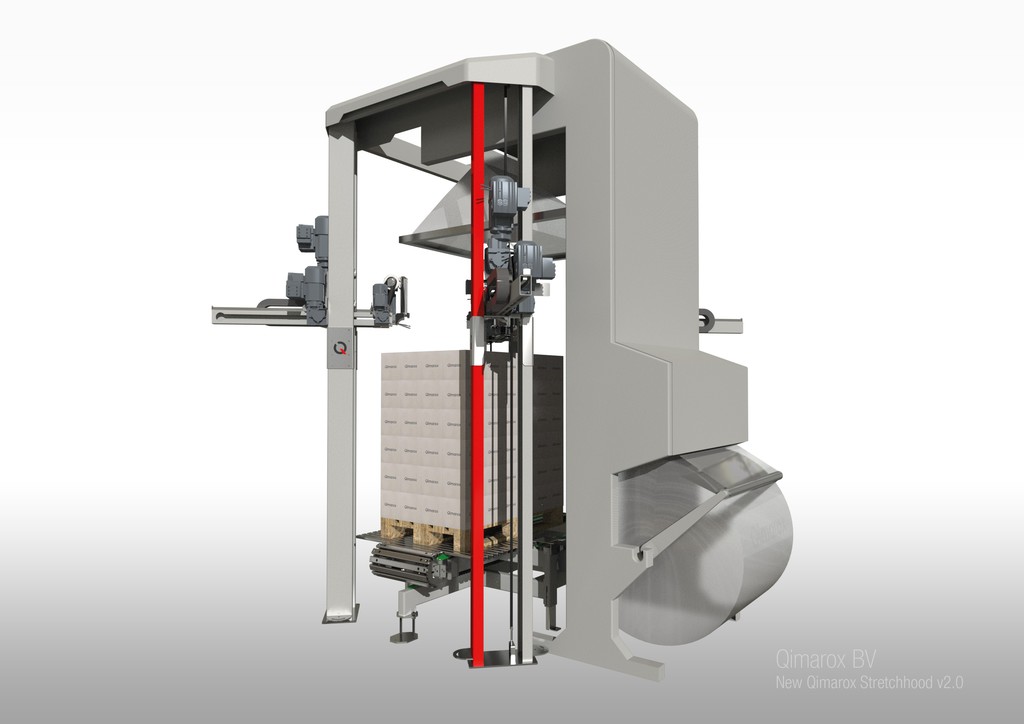

Qimarox has launched an improved version of the OEM stretch hooder it added to its product range last year.

A new feature is the patented concept whereby the tensioning arms, which stretch the wrap over the products, function independently in separate guideposts.

The lack of a framework (in which the tensioning arms are traditionally connected) improves the flexibility of the design of the standard stretch hooder. The position of the guideposts is determined in the project specifications, allowing the stretch hooder to be more adaptable. This opens up the possibility of processing pallets from two different directions, allowing the machine to be used in corners.

The compact stretch hood machine has four tensioning arms that can stretch a stretch wrap taut and pull it over the loaded pallet. When the tensioning arms release the stretch hood, the boxes, bags or other products on the pallet can no longer move due to the elasticity of the film. Because the four tensioning arms can move horizontally in two directions, the stretch hooder can wrap any size of pallet.

Energy consumption is thus minimised as the machine doesn’t use power-hungry technologies such as pneumatics and hydraulics to power the tensioning arms, allowing end customers to save up to €3,500 on energy costs each year. In addition, the machine excels in ease of maintenance. Inspection of the machine or replacement of wearing parts can all take place at ground level, so moving machine parts are not required for service and maintenance work.

Like all its other components – such as palletisers and vertical conveyors – Qimarox supplies the stretch wrapper to specialised and trained Certified System Partners without a control system. These system partners are thus given the opportunity to combine the control system of the machine with that of the other end-of-line packaging system components. This not only provides better integration, but also simpler control and lower investment and maintenance costs.

- Qimarox Prorunners are multi-purpose and can fit any layout

- Qimarox to exhibit at Promat

- Qimarox shortens delivery to two weeks

- Automated pallet building from containers

- Drones for palletising

- Simplified integration

- 20 years of business

- Faster and easier installation

- Stack loaded pallets quickly and easily

- Securyfence simplifies exchanging mesh panels and doors

/GRABOMATIC LOGO-tn.jpg)