Low breakage rate impresses

A pallet pool for the beverage industry replaced wood pallets with plastic, saving money.

Dranken Pallet Beheer Holland (DPB), the joint pallet pool for Dutch beverage producers and breweries, replaced their wooden pallets with plastic pallets from Cabka-IPS.

Part of the objective with the new pallet was to offer all pool participants the highest quality at a low cost while improving occupational safety.

Before the changeover, 800,000 wooden pallets were in circulation in the DPB pool. These caused high repair costs, dirt due to chips and shavings, increased weight in wet conditions, and high disposal costs for heavily damaged or contaminated pallets. For this reason, the new heavy load pallets made of plastic had to be tough, durable, significantly lighter, less prone to repairs, and ecologically feasible at the end of their service life.

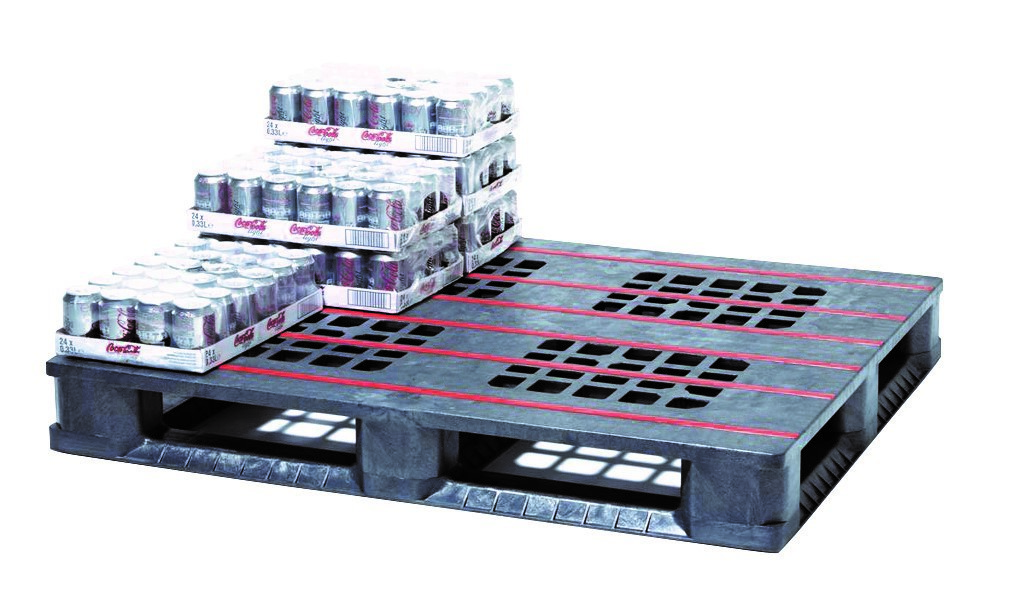

With the BPP i9, Cabka-IPS developed a tailor-made load carrier that met these requirements. As the successor of the wooden pallet, it was important to DPB that the BPP i9 would seamlessly fit into the existing storage and transport systems, which were configured for handling the wooden pallets. The forklift pockets, deck height, and blocks of the BPP i9 thus feature the same dimensions. The measurements are 1200 x 1000 x 169 mm.

{EMBED(895312)}

The BPP i9 weighs 25 kilograms – 15kgs lighter than the wooden pallet. On the one hand, this makes everyday handling of the pallets much easier for the production specialists. On the other hand, the lower weight leads to a significant reduction in CO2 emissions in the logistics centres, warehouses, and during transport by truck. Moreover, improvements were made in terms of load securing and occupational safety: Anti-slip strips secure the transported goods on the pallet; rubber blocks under the pallet prevent slipping, particularly with block stacking; rubber stoppers under the deck prevent slipping from the fork.

The most significant advantage of the BPP i9 for the participants of the pallet pool is the pallets' stable design. As the comparison of breakage rates shows, the pallet is considerably more resilient and durable than its wooden predecessor. While the wooden pallets had a breakage rate of 25% annually, the current annual breakage rate of the BPP i9 is only about 6%. On average, the pallets complete about nine trips in the DPB pool per year. This means the breakage rate is less than 1% per trip. This considerably reduces repair costs. Less damage to the pallet also means less damage to the goods. Using the BPP i9 has yielded a significant reduction in broken goods during production and processing, particularly in terms of sensitive goods such as glass bottles or cans.

Thanks to the wide-ranging cost savings, an important overriding goal has been achieved: The monthly rental fee paid by all pool participants for using the plastic pallets was significantly reduced. A total of 530,000 pallets are now in use in the DPB's pallet pool.

The BPP i9 has been manufactured from recycled materials and worn-out pallets are used as raw material for new pallets and thus continuously recycled in a closed circuit.

{EMBED(895311)}