| Home> | Industry Sector | >Distribution | >Learn how smaller van loading practice is evolving |

| Home> | Goods In & Out | >Loading bay equipment | >Learn how smaller van loading practice is evolving |

| Home> | Goods In & Out | >Loading bay safety | >Learn how smaller van loading practice is evolving |

Learn how smaller van loading practice is evolving

23 September 2019

Supporting the increasing trend for logistics companies to make next or even same day deliveries with smaller vans, Ian Langan, technical director at loading bay specialist Thorworld Industries, advises on the benefits of van docking ramps for speedy and safe dispatch.

The UK delivery industry is constantly evolving. As lead times become tighter and higher customer expectations for home delivery become commonplace, changes are needed to realise what is becoming a new distribution norm.

Increasingly, we’re seeing logistics companies adapt existing working practices and bolster lorry or container fleets with smaller, more responsive transit vehicles as an alternative to, or in conjunction with articulated lorries.

As such, the loading bays that support distributors’ operations are having to be suitably adapted to safely facilitate changing systems.

Whilst most articulated vehicles – owing to their height and volume capacity - can be best prepared for dispatch using a combination of height-set loading platforms and container ramps, vans need loading docks that are set at a lower position.

So, to enable customers to load vans from warehouses using the HGV docks they already have in place, we provide yard ramps, manufactured in various sizes and widths and purpose-built to provide ideal access for smaller, swifter vehicles.

These cleverly designed ramps easily enable existing loading docks to undergo an almost instant transformation that can safely accommodate different delivery vehicles. Ramps and supporting platforms can be designed so they are flush with the dock height, or made suitable for placement below the dock, so ‘vehicle floors’ can be ‘brought closer’ to the loading dock level. We can also supply-side platforms with access steps, fitted handrails and a variety of decking options if required.

Built to withstand different capacities, and designed in appropriate widths, incline lengths and level-off or platform lengths, we manufacture to order, depending on our client’s exact requirements.

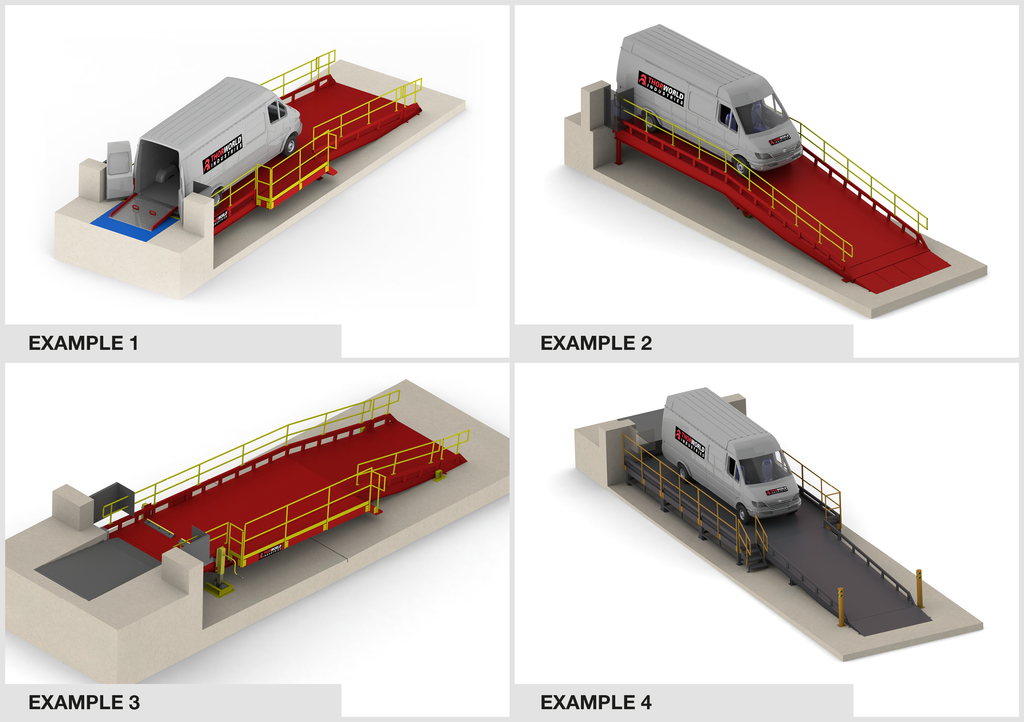

- Example 1: A fixed height application that enables the van deck to be closely positioned to the loading dock level and accessed using a removable dock plate.

- Example 2: A fixed height ramp designed to raise the van to the same height as the loading dock.

- Example 3: A ramp that can be adjusted using trailer landing legs mounted to either side.

- Example 4: A modular platform to create a larger working area.

/GRABOMATIC LOGO-tn.jpg)