| Home> | Automation | >Conveying components | >Bulk scanning capability extended |

| Home> | Industry Sector | >Distribution | >Bulk scanning capability extended |

| Home> | Warehouse IT | >Hardware | >Bulk scanning capability extended |

Bulk scanning capability extended

08 October 2018

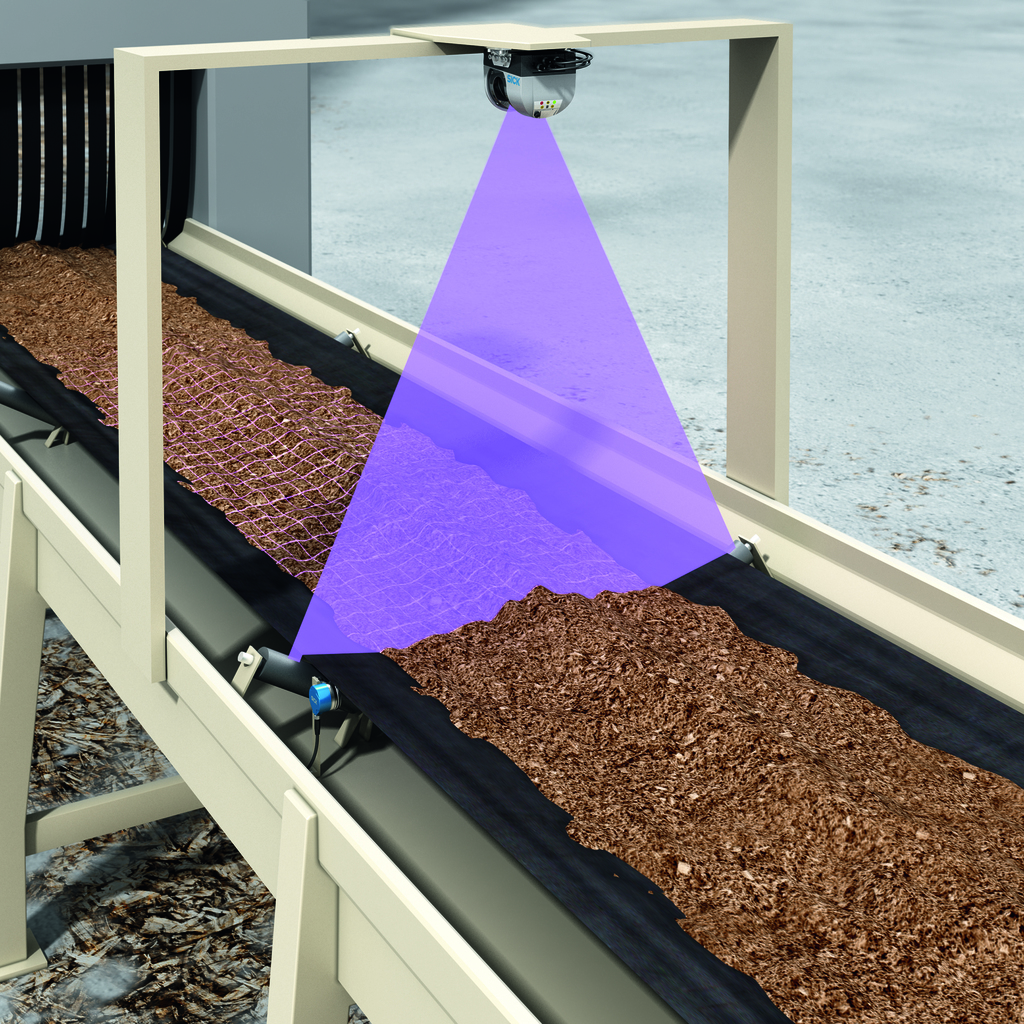

SICK has extended its LMS Bulkscan laser scanner offering, so that more users can benefit from non-contact, continuous measurement of volume and mass throughput of bulk materials on conveyor belts.

The SICK LMS111 Bulkscan provides highly-accurate, delay-free volume and mass flow measurements to maximise throughput of a wide range of bulk materials, such as in recycling and materials handling, and including fertilisers, seeds, grain and bulk harvested foods, as well as including gravels, sands and cements. Compact, and easy-to-integrate, the LMS111 Bulkscan can be designed into new lines or easily retrofitted onto existing conveyors.

The SICK LMS111 Bulkscan is said to be a cost-effective alternative to a conventional beltweigher that offers the wear-free, low-maintenance advantages of non-contact, real-time measurement. The multi-echo, time-of-flight laser scanning technology enables a reliable output of the material’s volume and mass flow. In addition, the material’s centre of gravity is continuously monitored to help avoid uneven loading and resulting belt wear.

“The new SICK LMS111 Bulkscan presents a value-added alternative to a standard belt scale and is a robust and consistent performer even in dusty production environments or when mounted behind glass,” explains Darren Pratt SICK UK’s national product manager for industrial instrumentation.

“By measuring the load height profile every 20 milliseconds, the LMS111 Bulkscan delivers an accurate, continuous profile measurement. It then works out the volume of the material using the belt speed which can be provided as a fixed value or input via an encoder in the case of a variable speed belt. The mass is computed from the volume and a known density of the material.

“Volume is more important than mass for many production processes, making Bulkscan an ideal alternative to beltweighers in conditions where the density of material changes significantly. Asymmetrical belt filling or unequal bulk distribution can cause off-track running. The load height and centre of gravity also have important wear, energy efficiency and safety implications in bulk conveying. As it’s non-contact, there is nothing to wear out with the LMS Bulkscan and it remains accurate without the regular recalibration needed for conventional scales.”

The LMS111 Bulkscan is easy to install and set up in a vertical (nom. 5o) alignment for accurate profile measurement. Using the pulsed, time-of-flight laser measurement system with a 190o wide field of view, the unit can be applied to the narrowest and widest conveyors. The instrument outputs three analogue signals via the BAM100 processing unit accessory, or delivers three digital signals that can be assigned to a bulk quota or for condition monitoring. A TCP/IP interface ensures easy connectivity with a PC, factory SCADA and PLC communications networks.

The SICK LMS111 unit is compact, measuring only 152mm x 102mm x 105mm, so is easy to install in a wide variety of locations. It can be mounted up to 10 metres above the conveyor, ambient operating conditions range from +50oC to -30oC, and environmental protection is rated at IP67.

The SICK LMS111 complements the LMS511 Bulkscan PRO which provides additional measurements and is designed for operation in more challenging dusty and dirty conditions, including the most arduous ambient conditions.

- Scanner with OCR

- Multi-beam protection

- Performance in adverse conditions

- Image-based code reader

- Quick reading even in tough applications

- Light curtain detects forklifts

- End the stop-start frustration of driverless forklifts

- AppSpace yields LabelChecker for SICK

- Next-gen light array sensors for high speed sorting and handling

- Snapshot sensor for 3D detection and collision warnings

/GRABOMATIC LOGO-tn.jpg)