| Home> | Automation | >AGVs | >End the stop-start frustration of driverless forklifts |

| Home> | Lift trucks | >Fleet management | >End the stop-start frustration of driverless forklifts |

| Home> | Lift trucks | >Warehouse | >End the stop-start frustration of driverless forklifts |

End the stop-start frustration of driverless forklifts

04 October 2018

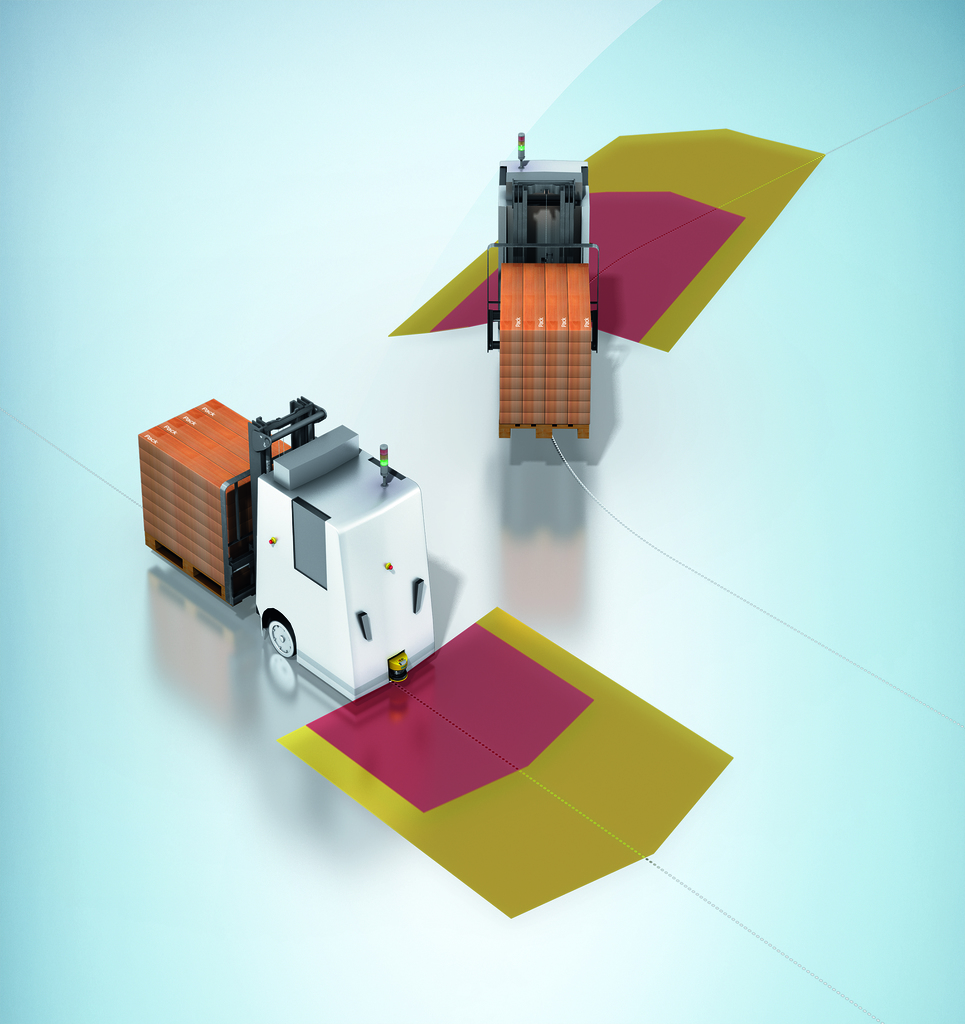

SICK has developed the Safe AGV Forklift, which allows an AGV to operate productively when the forks are in the load carrying position.

The PLd/SIL2-certified safety solution is said to solve a common stop-start frustration that slows operation and leads to wear and tear of Automated Guided Vehicles (AGVs) fitted with a forklift – when the protective laser scanning fields are infringed because the forks are down, the AGV must be brought to a safe stop.

Designed specifically for AGV forklifts with a drive wheel, the SICK Safe AGV Forklift integrates two SICK laser scanners providing protective fields in front and behind the vehicle, with a SICK Flexi Soft controller and a SICK encoder to monitor the speed of the vehicle.

Easily incorporated into a new AGV Forklift design or retrofitted onto existing vehicles, the SICK AGV Forklift is a functional safety system designed to meet both current EN1525 and forthcoming ISO 3691-4 safety standards.

Says Seb Strutt, SICK UK’s senior product manager for Machinery Safety: “When the SICK Safety Laser Scanner protective field is obscured by the forks carrying a load, or during loading and unloading, the AGV can continue to proceed at a safe speed of 0.3m/sec, without requiring personnel supervision.

“In addition, the SICK scanners operate a warning detection field as well as a protective stop field, so that the AGV slows when objects are sensed at a distance, reducing the wear and downtime associated with constant start/stop operation.”

Laser scanner

- Brings crane automation up to speed

- Master Data Analyzer stops storing and shipping fresh air

- Data control

- Data reading in atex environment

- Simpler and easier robot guidance

- Bulk scanning capability extended

- Barcode scanner for industrial use

- 3D camera with certified safety launches

- Next-gen light array sensors for high speed sorting and handling

- Versatile incremental encoders

/GRABOMATIC LOGO-tn.jpg)