| Home> | Automation | >Automated handling | >Science in spirals |

| Home> | Industry Sector | >Food & drink | >Science in spirals |

ARTICLE

Science in spirals

05 July 2018

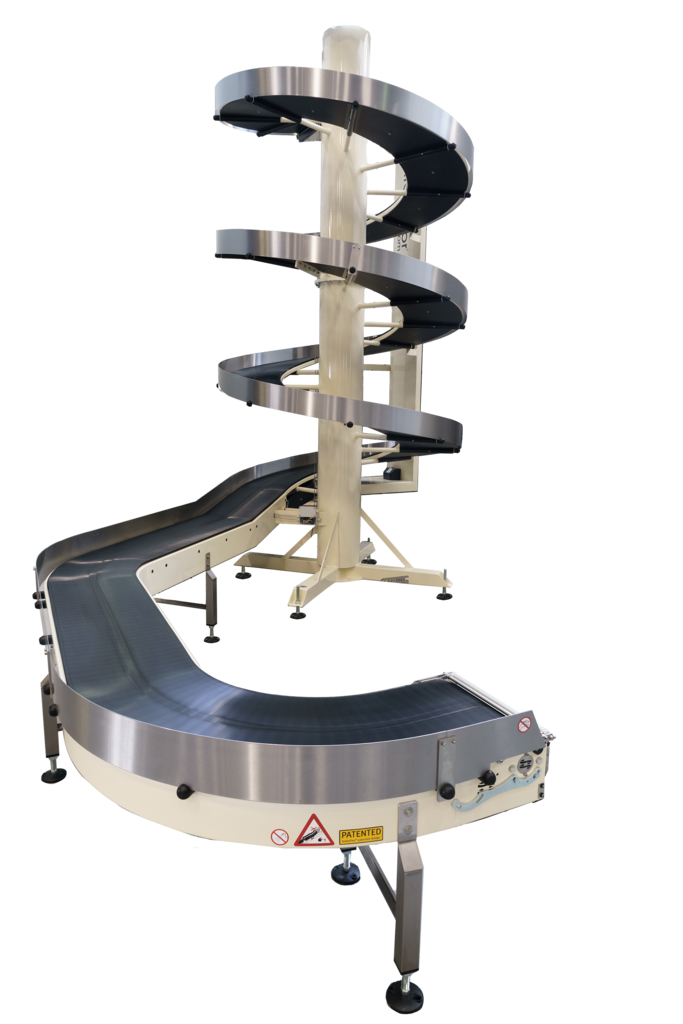

A German producer of chocolate-based sweets needed to transport cartons containing the candy down with the minimum amount of transfers possible.

When rearranging parts of the line, one of the main challenges is figuring out how to connect the current machines with the new solutions as efficiently as possible. In this particular case, the existing conveyor that would feed the elevator with products was too short to connect to it directly. This meant they needed to install two curved conveyors and two straight parts just to bridge the gap. Not only did this mean adding four unwanted transfers but also adding extra controls and maintenance, increasing costs significantly.

MORE FROM THIS COMPANY

OTHER ARTICLES IN THIS SECTION

/GRABOMATIC LOGO-tn.jpg)