| Home> | Warehouse Storage | >Racking & shelving | >Push back system |

Push back system

05 September 2013

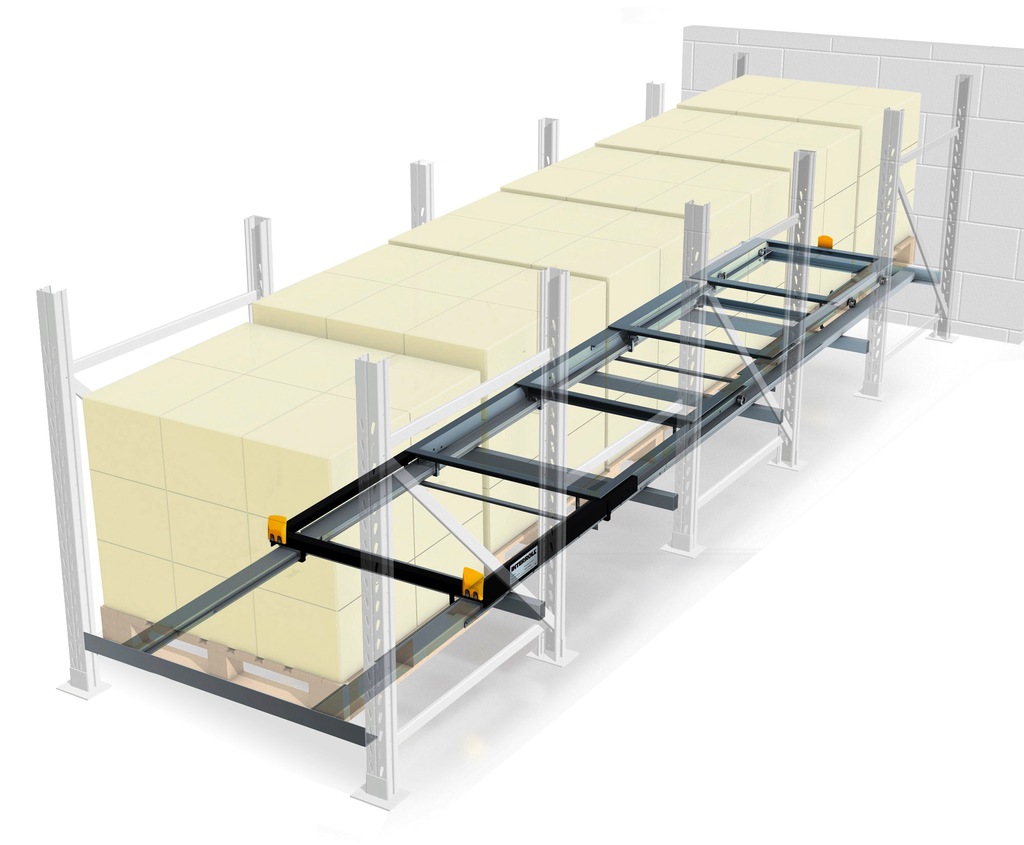

Enabling an increase in storage of 30% and a reduction in energy consumption of 20% Interroll’s Push Back system (LIFO) is running successfully in one of Dole Food’s workshops in Korea.

The order was received last year by Nongshim ENG – one of Interroll’s partners and a reliable system integrator in Korea, and it includes 700 pallets positions with 3, 5 or 7 pallet deep lanes.

"In the past, we used drive-in rack systems, which not only require comprehensive forklift driver training but also bring challenges in terms of safety in the working environment," commented Mr Nam-Kuk Kim, director of Dole Korea.

"Interroll Push back system is very user-friendly and we don’t need to drive into the rack, which can save us 25% of our time.”

- Drum motor makes the cut

- Tapered elements for curved roller conveyors

- A novel solution

- Quick conveyor assembly with modular concept

- Energy-saving drives

- Optimum solution for 24V DC conveyor technology

- Carton Versi Flow converts pallet racking into dynamic carton flow store

- Interroll Carton Flow picked for fast-moving plumbing components

- Interroll Automation GmbH appoints MD

- Interroll RollerDrive EC310 - the most energy efficient all-purpose drive

/GRABOMATIC LOGO-tn.jpg)