| Home> | Warehouse Storage | >Warehouse storage | >Premier parts storage |

Premier parts storage

15 January 2015

With space at a premium, picking and storage systems which maximise utilisation of available building volume are assuming greater importance at both distribution centre and dealership level within the automotive sector.

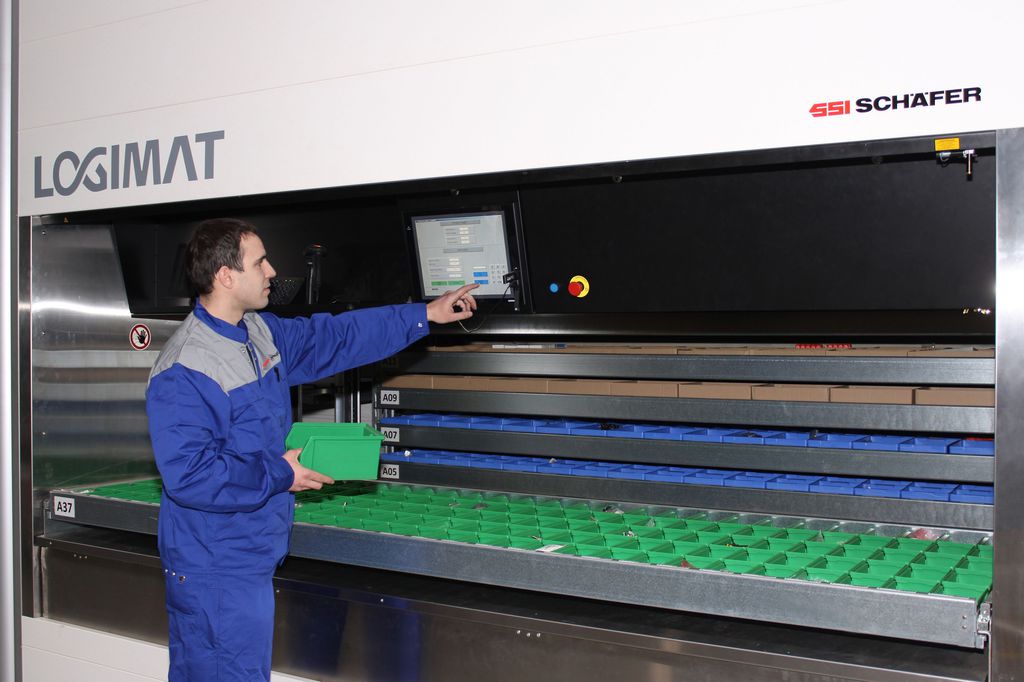

2012 saw the completion of an extensive, new Midlands distribution centre for one prestigious car manufacturer, with the internal layout, design and installation of storage and automation systems completed by SSI Schaefer.

Solution design experts from Schaefer worked closely with the manufacturer’s logistics team, analysing distribution data and factoring in growth plans, to provide an efficient and accurate storage and picking system, which would accommodate some 65,000 different part numbers (SKUs), at a level of 97% availability.

This system enables a rapid response to a continual stream of orders placed throughout the day and ensures a guaranteed next day delivery service to all locations within the company’s national dealership network.

- Space optimisation

- Fast and flexible storage & retrieval

- Fashion retailer goes omnichannel with goods-to-person picking

- Putting safety first

- Watching the wage bill

- Schaefer hosts lean workshop

- High density cold storage

- Fashion retailer opts for Schaefer

- Intelligent storage system

- Component supplier gets a lift

/GRABOMATIC LOGO-tn.jpg)