| Home> | Automation | >End-of-line equipment | >Speed & flexibility |

Speed & flexibility

18 May 2015

According to Qimarox, the company's innovative product lifts, pallet lifts and palletisers are proof that high capacity and flexibility can go together with low operating costs and a high degree of durability.

Qimarox’s Highrunner mk7 is an innovative palletiser that combines the capacity of a conventional palletiser with the flexibility of a palletising robot. The unit can carefully and accurately position a wide range of product types and sizes into any desired pattern and deposit them on the pallet layer by layer.

The Highrunner mk7 features a patented pattern-formation conveyor, which is always located at the same height as the top of the pallet. This allows the layers created on the pattern-formation conveyor to be deposited at high speed, which makes for a particularly high capacity.

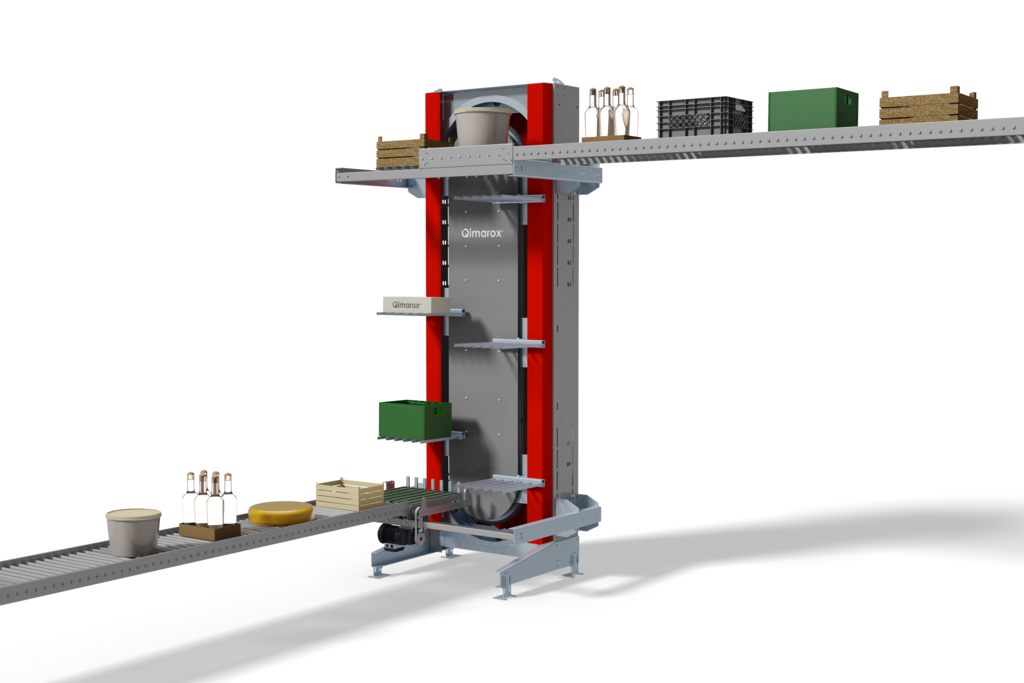

The Prorunner mk5 works according to the paternoster principle, which results in a versatile vertical transport system with a capacity of 2000 products per hour. Because a single elevator system can be used for both upward and downward product flows, the Prorunner mk5 is ideal for vertical sorting.

The Prorunner mk10 – an extremely robust product elevator for pallets of up to 2,000 kg – is the latest product in Qimarox’s range of material handling systems. This product lift can transport up to sixty pallets per hour ten metres upwards.

- Palletisers & vertical transport systems

- Heavier pallets reach higher level

- Qimarox shortens delivery to two weeks

- Automatic order picking

- Qimarox to exhibit at Promat

- Rolling On label

- Modular lift handles pallets up to 2000kg

- Automated pallet building from containers

- New stretch hooder can be used in corners

- Double capacity vertical conveyor for AMRs

/GRABOMATIC LOGO-tn.jpg)