| Home> | Automation | >Automated handling | >TVH invests in automated shuttle based DC |

| Home> | Automation | >Automated storage | >TVH invests in automated shuttle based DC |

| Home> | Industry Sector | >Manufacturing | >TVH invests in automated shuttle based DC |

TVH invests in automated shuttle based DC

08 April 2016

Increased volumes and lack of storage space prompted TVH to partner with TGW in an expansion of its distribution facility.

TVH distributes parts for materials handling equipment around the world, processing 8,000 orders per day. The number of stored items reached 500,000.

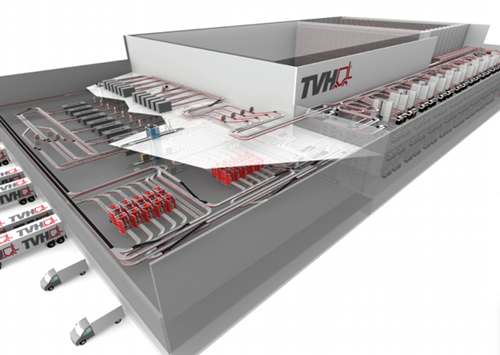

Due to the growing volumes of orders and increased numbers of stored items, to ensure future demand will be met and sustain growth, TVH will be building a 12,000 sq m automated distribution centre from which orders will be picked, packed and shipped. The new distribution centre aims to increase TVH customer service by increasing stock lines and improving throughput. The DC is an addition to the existing facility which will remain part of the overall operation, the two facilities will be linked via a bridge structure.

TGW have been selected as the TVH automation partner and will integrate a TGW Stingray shuttle storing plastic totes. The total Stingray shuttle system will have 13 aisles and 50 levels. TVH will be able to store more than 400,000 totes in the 25m high shuttle block.

This “pick engine” will deliver stock totes to the goods to person pick-stations. A TGW KingDrive conveyor network will connect all the storage and operational areas together. TGW Natrix sorters also form part of this conveyor network. The new DC will go-live in 2019.

- Machine learning in intralogistics

- Flat system a good fit

- TGW Group appoints new Sales Director

- eGrocery specialist Picnic invests in further automation

- Puma to build vast world class logistics centre

- Calling the Commissioner

- Mango builds highly automated DC

- Puma logistics hub goes live

- Retrofit expands capacity

- Expanded storage capacity

/GRABOMATIC LOGO-tn.jpg)