| Home> | Lift trucks | >Attachments | >ATEX drum rotator |

| Home> | Lifting & moving | >Heavy Duty Lifting & Moving | >ATEX drum rotator |

| Home> | Facilities Management | >Recycling | >ATEX drum rotator |

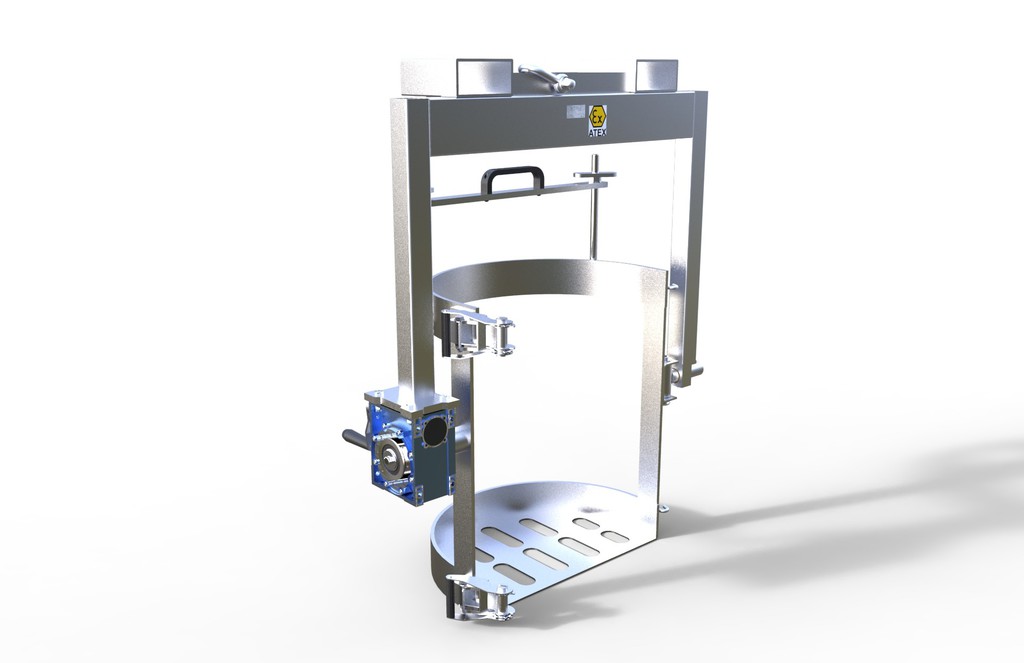

ATEX drum rotator

29 July 2016

A UK manufacturer of forklift attachments has offered increased confidence of working in high risk areas by manufacturing and supplying one of its clients with a certified ATEX solution.

Contact Attachments supplied one of its heavy-duty Drum Rotators to Merseyside head-quartered Qualitech Environmental Services to aid its manual handling of potentially hazardous products.

Qualitech provides waste management, recycling and industrial cleaning services to a variety of industries, and due to the nature of its products it was essential for the Drum Rotator to conform to the latest ATEX Directive, and provide the firm of an even safer method of transferring and transporting products across its sites.

Andrew Kelleher of Qualitech Environmental Services says: “As a project manager working on a high profile decommission project, I approached Contact Attachments with a request to create a bespoke FLT drum handing attachment which needed to be fully ATEX compliant (zone 2). After speaking to the Contact design team, I was presented with a full proposal including technical specification and drawings, and lead times within just 24 hours.

“Contact delivered the attachment on-schedule and in great condition, and fully certified (ATEX). We received an excellent, bespoke piece of kit which was tailored to our own individual and very specific requirements. Top quality workmanship and service from a superb supplier.”

Dave Manuel, tech sales direction at Contact Attachments adds: “We pride ourselves on providing our clients with not only a high quality service, but also complete confidence in the safety of all our products. The ATEX certification essentially allows the products to be used safely in an environment that may be considered hazardous and potentially explosive. The stainless steel used within the drum rotator is suitable for use in these areas and can provide the operator with complete peace of mind.”

- Drum attachments

- Accident risk reduced

- Contact Attachments launches ‘Summer of Safety’ campaign

- Forklift Safety Cage assists repair work

- Forklift transfer platform provides safe solution

- Attachments catalogue

- Handles sandbags with ease

- Specialist attachments for nuclear disposal project

- Will the Beast from the East return?

- Tipping skip

/GRABOMATIC LOGO-tn.jpg)