| Home> | Automation | >Picking & sortation | >Automatic order picking |

| Home> | Industry Sector | >Retail/E-tail | >Automatic order picking |

Automatic order picking

14 April 2013

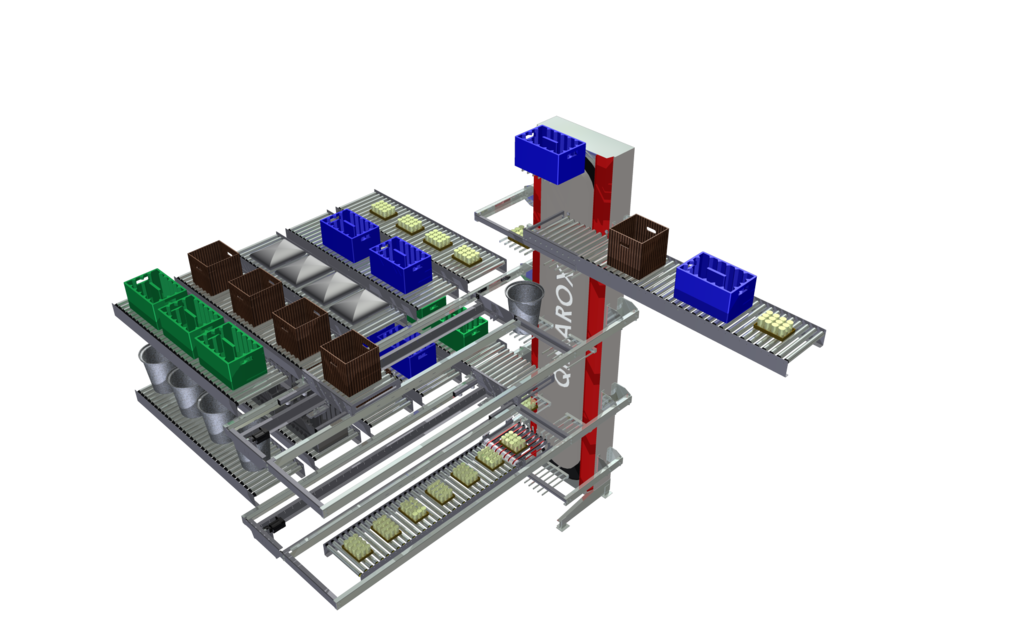

Capable of handling up to a thousand products, containers, or cartons per hour, Qimarox has developed a new automated order picking system: Collect & Sort.

Central to the system is the Prorunner mk5, the vertical transport system from the company that evolved from Nedpack in 2012. Products from conveyor channels at different levels are fed out fully automatically and placed on the correct outfeed conveyor in the direction of the forwarding department or palletising station.

Approximately 15 channels can be served per level by a roller conveyor module; the Prorunner mk5 can reach a maximum height of 15m and the number of levels can thus be extended to about 20 levels. This brings the total of pick locations up to 300.

In addition to being used as an order picking system, the product can also be used as a sequencer in mixed palletising systems.

- Heavier pallets reach higher level

- Double capacity vertical conveyor for AMRs

- Securyfence simplifies exchanging mesh panels and doors

- Stack loaded pallets quickly and easily

- 20 years of business

- Automatic order picking

- Qimarox to exhibit at Promat

- Compact vertical pallet transport

- Speed & flexibility

- Qimarox Prorunners are multi-purpose and can fit any layout

/GRABOMATIC LOGO-tn.jpg)