| Home> | Automation | >Conveying components | >Drum motor moves into servo drive applications |

Drum motor moves into servo drive applications

03 September 2014

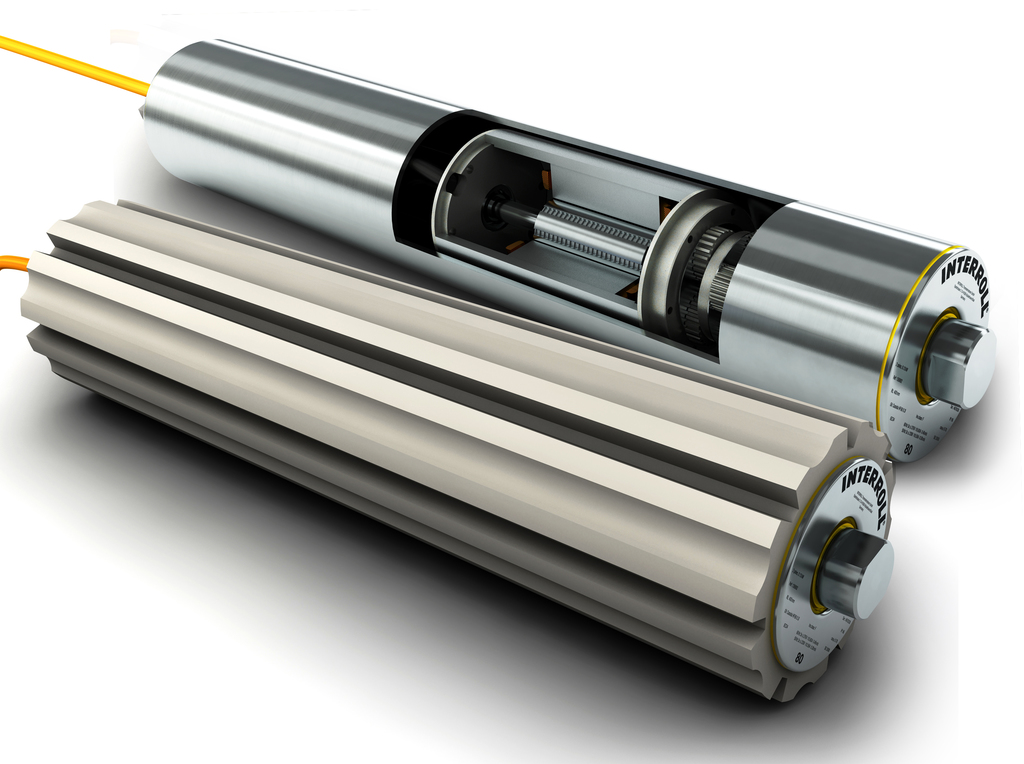

At PPMA 2014 Interroll will exhibit integrated drive solutions and showcase its new high torque Synchronous Drum Motor.

Developed specifically for the food processing and packaging sectors, this is the most powerful and eco-friendly energy efficient hygienic conveyor belt drive ever developed by Interroll - providing a one drive system to suit all needs and speeds (0.01 m/s up to 4.5 m/s). Its capabilities now expand into applications previously reserved for servo-drive technology.

Combined with an integrated encoder or other feedback system, the Synchronous Drum Motor can accelerate from zero to 100% of the maximum speed in milliseconds. It can be precisely controlled at both extremely high and ultra low speeds with fast and timely exact positioning.

Manufactured with EHEDG approval, FDA recognition and IP69K protection rating, the Interroll Synchronous Drum motor requires zero maintenance and can be operated in wet and high pressure wash down applications.

- Cycling products distributor invests in advanced conveyor

- Interroll couriers favour with express parcel sorting

- Optimum solution for 24V DC conveyor technology

- Interroll to demonstrate greater power at Drives & Controls

- Modular conveyor platform boosts productivity

- Picking among show highlights

- Push back system

- Conveyors for chilled and deep-freeze areas

- Motorised drive solutions

- Modular solutions

/GRABOMATIC LOGO-tn.jpg)