| Home> | Industry Sector | >Chemicals & Pharma | >Motorised drive solutions |

| Home> | Automation | >Conveying components | >Motorised drive solutions |

Motorised drive solutions

18 May 2015

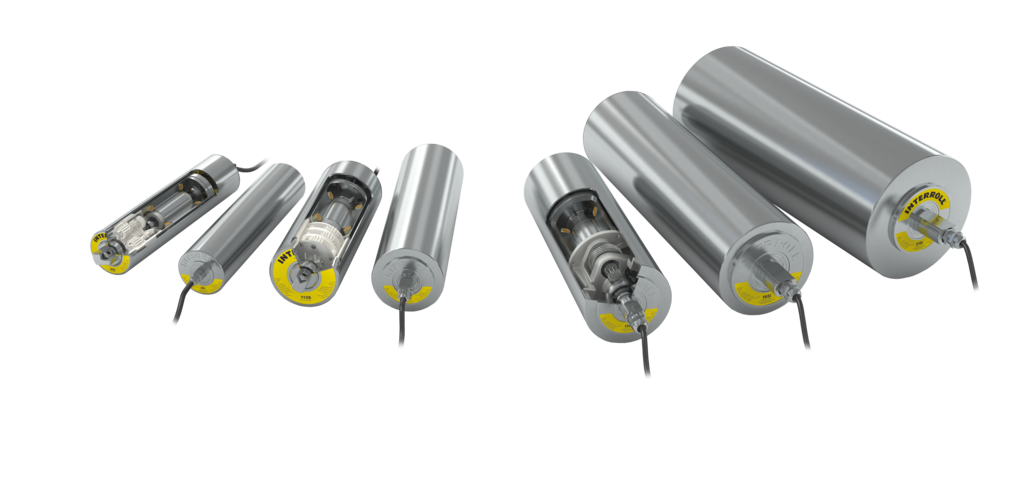

Designed to provide a quick and easy way of building maintenance-free, hygienic and energy efficient belt conveyors, ZPA accumulation roller conveyors and associated material handling equipment, Interroll offers a proven and diversified range of innovative IP66/IP69K Synchronous and Asynchronous Drum Motors and IP54/IP66 24VDC RollerDrive.

The company has adapted drum motors to suit customers specific handling applications and all types of belt conveyor systems including modular plastic belts, with FDA approved profiled rubber/ PU lagging, stainless steel or polymeric sprockets to provide the perfect drive solution.

Highly energy efficient and fully sealed for life, Interroll drive solutions are resistant to dust, oil, grease and impervious to high pressure cleaning and give long life trouble free operation.

- Hilton Campbell appointed new Interroll UK MD

- Dynamic storage solutions on show at IntraLogisteX

- Energy-efficient RollerDrive provides higher sustainability

- Smart conveying systems optimise tyre manufacturers' material flow

- Space saving solution

- Dynamic storage solution

- Interroll Pallet Control PC 6000 enables zero-pressure pallet conveyance

- New Synchronous Drum Motor: energy-efficient and powerful

- Zero-pressure pallet conveyance

- Hermes Fulfilment reduces energy consumption thanks to Interroll RollerDrive

/GRABOMATIC LOGO-tn.jpg)