| Home> | Automation | >Conveying components | >Study compares motors in food industry |

Study compares motors in food industry

03 March 2017

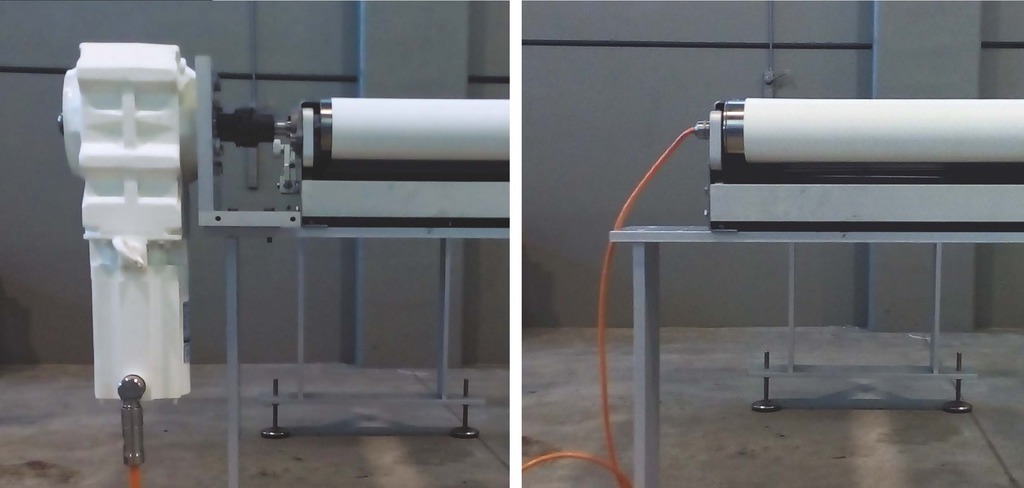

The Department of Food Science at the University of Parma in Italy, in collaboration with the Interroll Group, carried out a comprehensive system comparison between two distinct drive technologies: traditional gear motors against Interroll drum motors.

Prof. Davide Barbanti and his research team conducted a far-reaching comparison along six evaluation criteria: hygiene, installation and maintenance, energy efficiency, noise, working temperature and space requirements.

Three cases were designed to simulate different areas of a food processing plant, from a washdown application to a packaging line - run over a nine-month period and yielded interesting results. This showed from a food safety point the drum motor was particularly attractive technology for conveyor belts in the food industry.

Downloaded the white paper, “Comparative evaluation between gear motors and drum motors in the food industry,“ from the Interroll website: www.interroll.com/downloads.

- Interroll Pallet Control PC 6000 enables zero-pressure pallet conveyance

- Expanded platform

- Cross belt sorters from Interroll an economical solution

- Turning pallet racking into dynamic carton flow storage

- Interroll launches modular conveyor platform

- Interroll demonstrates excellence through innovation

- Intelligent conveying system improves performance and reduces energy consumption

- Drop tray sorter launched by Interroll

- Push back system

- Belt curve offering expanded

/GRABOMATIC LOGO-tn.jpg)