| Home> | Automation | >Automated handling | >Exploiting Industry 4.0 |

| Home> | Automation | >Automated storage | >Exploiting Industry 4.0 |

| Home> | Automation | >Conveying components | >Exploiting Industry 4.0 |

Exploiting Industry 4.0

15 June 2017

So, what exactly is it all about? Can I go out and buy Industry 4.0? Is it a tightly written specification of what Industrial organisation is supposed to look like?

Simon Adams, MD of Werma UK says: "Industry 4.0 is a concept formulated by the German industrial community to encourage work towards developing ever more sophisticated technologies to automate and computerise the running of factories. This trend is also captured by the phrase “4th Industrial Revolution”. It captures the desire to work at removing “human machine interfaces” seen by their very nature as being a potentially vulnerable area simply due to the sometimes unpredictable nature of human behaviour and replace them with more automated computer driven systems.

Evolution not revolution

“The illustration below captures very neatly the tag that Industry 4.0 is the 4th industrial revolution but in trying to understand how it should apply to the management and development of our own businesses I prefer to call the whole thing “evolution not revolution” continues Simon.

Here in the UK Industry 4.0 is still a really new concept but already another tag is being widely used to coin the concept more clearly – Smart Factory.

Intelligent systems from Werma

Werma’s contribution to the debate comes in the form of three new smart and intelligent process systems all designed to play their part in eliminating HMI related weaknesses in process chains and replacing them with fail-safe automated systems.

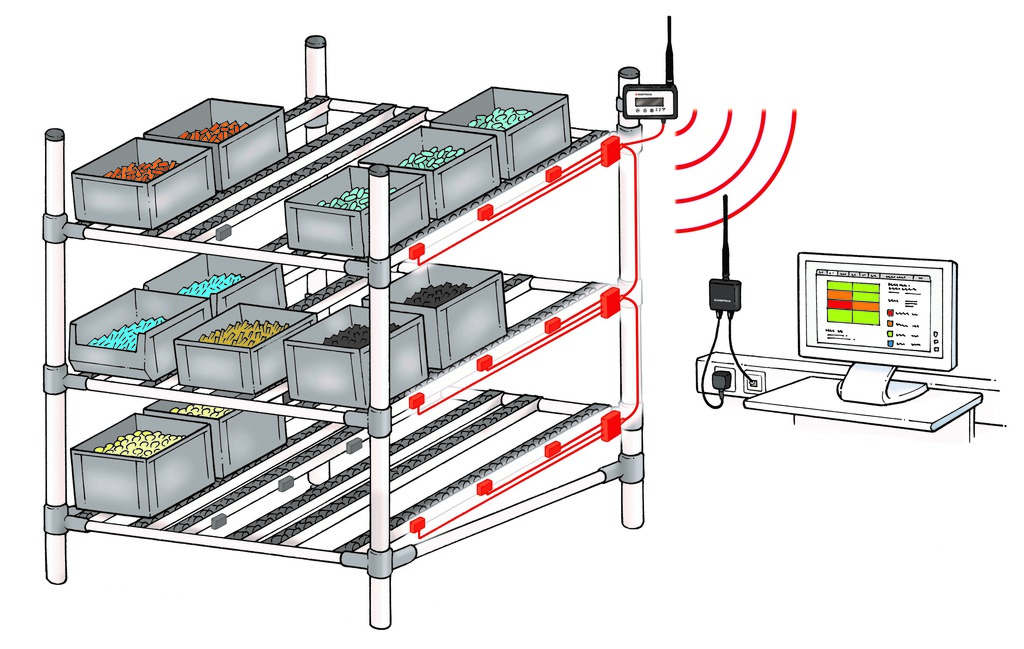

StockSAVER: the new Kanban system without cards

The system, simple to retrofit to existing FIFO flow racking, solves many typical Kanban issues, increases significantly the floor space for value adding activities and increases cash flow. StockSAVER automatically calls up material replenishment requirements and thereby reduces the margin for human error and will significantly cut the amount of line-side safety stock being held.

StockSAVER deploys sensors fitted to the FIFO flow racking system to detect the passage of all sizes of commonly used bins. Data on bin movements is transmitted wirelessly to a control station view on a PC and triggers automatically precise replenishment orders. It will give a transparency to the stock levels in the FIFO racks enabling a significant reduction in the requirement for safety stocks to be held there. The systems solves the problem of mislaid, damaged or untimely Kanban card re-ordering processes and most importantly negates the need for safety stocks line-side and will therefore improve also cash flow.

StockSAVER is simple to install and is easy to extend. Clear and simple Kanban displays keep Production and Logistics informed and enables the process to become more robust and less susceptible to errors.

SmartMONITOR: the intelligent alternative for machine monitoring and data collection

WERMA’s SmartMONITOR helps to make processers lean, faster and more efficient. The wireless based data collection and transmission system is easy to retrofit and enables analysis of the operation which in turn will lead to untapping growth potential and keeping you one step ahead of the competition.

“SmartMONITOR is the intelligent machine monitoring system alternative for companies who are looking for a quick and uncomplicated way of optimising their processes” comments Simon who continues; “the system will provide you with all relevant data on the performance of machines, equipment and manual workstations, simply with a couple of mouse clicks.”

Control station displays on the PC or automatic notification to your smartphone will help to reduce reaction to downtime considerably and help identify ways of optimising manufacturing processes. Detailed reports and analyses of the data can be produced automatically which will then show the possibilities to improve processes and increase productivity.

AndonSPEED Keeps things moving - a unique system for optimising warehouse logistics processes

Since 2016 AndonSPEED has been playing its part in optimising processes on manual workstations and in warehouse operations. The system is a unique and innovative intelligent monitoring and call-for-action system. Unlike traditional andon light systems AndonSPEED not only gives a clear local visual signal of a disruption or change in status on the line or workstation, but also documents and analyses downtime. The wirelessly connected system passes information to a control station display on a PC or screen and can also despatch call for action e-mails automatically to personnel required to intervene and resolve a problem.

To find out more about Werma and the new systems please contact:

Tel: 01536 486930

- WERMA extends factory in Germany

- Eliminate stock-outs

- Werma updates product catalogue

- Wireless remote switch

- Common sense system

- Free seminar at The Lean Workshop Group

- Kanban system without cards adds efficiency to FIFO racking

- Lights, towers & traffic lights

- Industry 4.0 process optimisation

- Wireless monitoring

/GRABOMATIC LOGO-tn.jpg)