| Home> | Lift trucks | >Fleet management | >Smart trucks minimise downtime |

Smart trucks minimise downtime

21 February 2019

You need an efficient logistics operation to keep your business moving, and this is only possible if all your trucks are up and running. Smart trucks can support this using data provided by telematics, says Toyota Material Handling UK.

Connected trucks will allow you to move towards predictive service, repairing your trucks before anything can happen, aiming for zero breakdowns. Here you will learn how a smart truck can help you improve your service for maximum uptime.

Quick and efficient service planning

Connectivity is key to efficient forklift service, and is one of the values of the Toyota Service Concept, our service approach based on the Toyota Production System. Thanks to this lean approach to service, we can offer you better service planning, more added value and less muda (waste), improving the overall efficiency of your logistics operations.

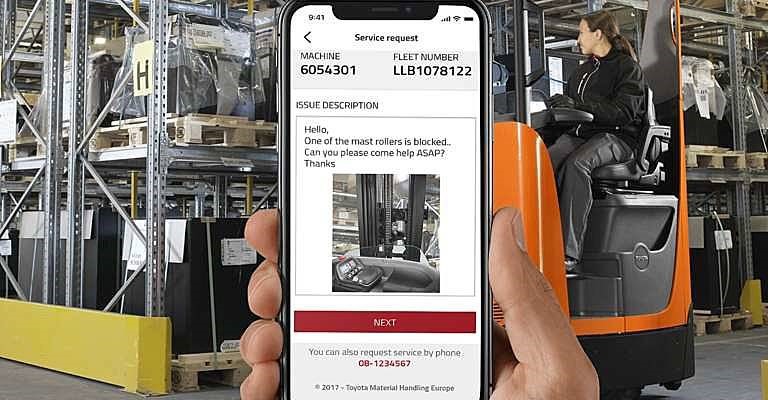

When connecting smart trucks via the I_Site application you are also able to directly request a service via the app. You can get in direct contact with a service team, and add a picture and/or a message. Service cost data is also available, connecting to Toyota's service data systems.

Real-time insights

Among the benefits of upgrading your smart trucks to I_Site is also the possibility to connect with Toyota's new mobile service platform for technicians, T-Stream. This service tool can integrate the data from connected trucks to the service technician, improving service efficiency. Field technicians who are armed with real-time insights can ensure factory equipment operates correctly and efficiently and verify running hours remotely. This eliminates unnecessary service visits and allows for better planning, which results in lower repair costs. T-Stream also enables streamlined servicing of connected trucks, with remote updates and activity-based maintenance, resulting in lower downtime of your trucks, decreasing your overall cost of ownership.

Maximum uptime

- Toyota takes gold

- Powered pallet trucks can help avoid injuries

- Aims to reduce handling risks

- Get hands-on with Toyota

- Toyota 50/50 truck on tour

- Refurbishment on film

- Toyota MHE to offer racking

- Toyota buys intralogistics software firm Viastore

- Automated pallet carrier launched by Toyota

- A host of innovations

/GRABOMATIC LOGO-tn.jpg)