| Home> | Automation | >Picking & sortation | >Automatic order picking |

| Home> | Warehouse Storage | >Warehouse storage | >Automatic order picking |

Automatic order picking

20 May 2013

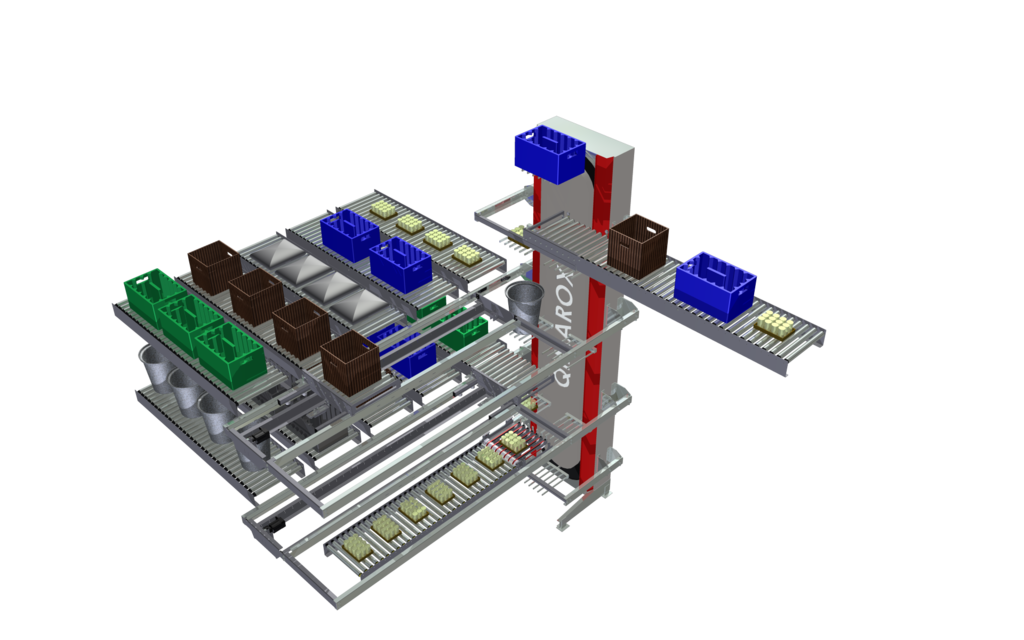

Handling up to a thousand products, containers, or cartons per hour, Qimarox has developed a new automated order picking system, ‘Collect & Sort’.

Central to this system is the Prorunner mk5 vertical transport system. Products from conveyor channels at different levels are fed out fully automatically and placed on the correct outfeed conveyor in the direction of the forwarding department or palletising station.

The system is suitable for products, containers, or boxes of at least 200 x 200 and up to 600 x 600mm, and that weigh no more than 50 kg. A special XL model can handle products up to 900 x 900mm.

As well as being used as an order picking system, the equipment can also be used as a sequencer in mixed palletising systems. The conveyor channels are then randomly filled with products at the front. They are then fed out at the rear, in the order in which the mixed palletiser wants to receive them.

- Reliable components delivery

- Double capacity vertical conveyor for AMRs

- 20 years of business

- Shorter delivery times

- Lifts & palletisers

- Qimarox to exhibit at Promat

- New stretch hooder can be used in corners

- Automatic order picking

- Stack loaded pallets quickly and easily

- Heavier pallets reach higher level

/GRABOMATIC LOGO-tn.jpg)